What is Rogers RT/Duroid® 6010 PCB?

Rogers RT/Duroid® 6010 PCB Manufacturer.Rogers RT/Duroid® 6010 PCB Manufacturer specializes in crafting high-quality printed circuit boards using Rogers RT/Duroid® 6010 materials. Our expertise lies in delivering reliable and high-performance PCB solutions tailored to meet diverse industrial and technological needs.

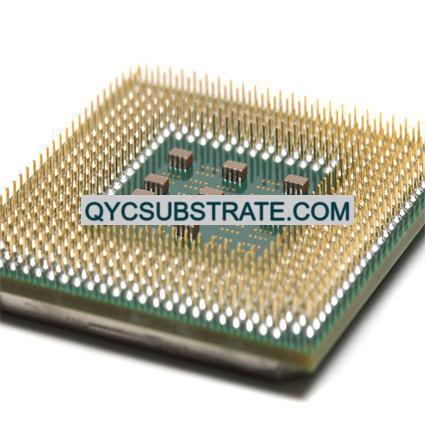

Rogers RT/Duroid® 6010 PCB is a high-performance printed circuit board (PCB) made from Rogers Corporation’s RT/Duroid® 6010 material. This material is known for its excellent electrical properties and mechanical stability, making it particularly suitable for high-frequency, high-speed and microwave applications.

Rogers RT/Duroid® 6010 material has low loss, stable dielectric constant and excellent thermal conductivity, allowing it to perform in high frequency bands (typically hundreds of megahertz to several gigahertz), high-speed signal transmission, and microwave technology outstanding. These features make RT/Duroid® 6010 PCB the first choice in wireless communication systems, radar technology, satellite communications and medical equipment.

Designing a Rogers RT/Duroid® 6010 PCB requires consideration of the special properties of its material to ensure circuit layout and placement of components to maximize its excellent electrical properties. Advanced computer-aided design (CAD) software is typically used for simulation and verification to ensure that the design meets expected high-frequency characteristics and stability requirements.

The process of manufacturing a Rogers RT/Duroid® 6010 PCB involves several key steps, including material preparation, lamination, drilling, electroless copper plating, patterning, metallization and final inspection. These steps ensure that the quality and performance of the PCB meet design standards and that it can operate reliably in a variety of environmental conditions.

Overall, Rogers RT/Duroid® 6010 PCB not only performs well in electrical characteristics, but also maintains stable performance under high temperatures, high frequencies, and complex electronic environments. Its wide range of applications covers many fields from communication infrastructure to aerospace technology, providing important support for the design and manufacturing of modern high-performance electronic systems.

These features make Rogers RT/Duroid® 6010 PCB an ideal choice for engineers and designers looking for superior performance and reliability in projects, whether in commercial applications or technology fields.

The types of Rogers RT/Duroid® 6010 PCB

Rogers RT/Duroid® 6010 PCB is a high-performance printed circuit board (PCB) based on Rogers Corporation’s RT/Duroid® 6010 material with a wide range of applications and types to choose from.

The single-layer Rogers RT/Duroid® 6010 PCB is the simplest form and is suitable for basic circuit design and low-complexity applications. They are typically used for projects that require rapid prototyping or are less expensive.

The dual-layer Rogers RT/Duroid® 6010 PCB features two layers of copper foil and an insulating layer. This type of PCB can accommodate more complex circuit designs, such as signal separation or light interconnect requirements.

Rogers RT/Duroid® 6010 PCB Manufacturer

Multilayer Rogers RT/Duroid® 6010 PCBs include three or more layers of copper foil and insulation. They are suitable for designs requiring higher electronic component density and complex signal transmission paths. Multilayer PCBs offer greater design freedom and higher performance potential.

High-density interconnect Rogers RT/Duroid® 6010 PCB is a specialized form of multi-layer PCB that allows for more complex circuit layouts through finer craftsmanship and routing density. They are commonly used in portable devices and high-performance computer systems.

Flexible Rogers RT/Duroid® 6010 PCB is a circuit board that bends and folds for use in tight spaces and applications that require flexible connections, such as wearables and flexible electronics.

Selecting the Rogers RT/Duroid® 6010 PCB type that suits your needs depends on the complexity of your project, performance requirements, and budget constraints. Single-layer PCBs are suitable for simple circuit designs and cost-sensitive applications, while multi-layer PCBs are suitable for projects requiring higher performance and complex layouts. Flexible PCBs and high-density interconnect PCBs are suitable for applications that require special physical properties or a high level of integration.

The types of Rogers RT/Duroid® 6010 PCBHow to Design a Rogers RT/Duroid® 6010 PCB?

Rogers RT/Duroid® 6010 PCB mainly includes single-layer boards, double-layer boards and multi-layer boards. Single-layer boards are suitable for simple circuit layouts and low-complexity applications, while double- and multi-layer boards can support more complex circuit designs and higher integration levels. Multilayer boards are particularly suitable for applications where multiple electronic components need to be accommodated in a limited space.

There are several key steps to follow when designing a Rogers RT/Duroid® 6010 PCB to ensure the final product meets the requirements of high-frequency and high-speed applications. First, a detailed analysis of circuit requirements and specification requirements is required. Next, select the appropriate PCB thickness and number of layers, usually based on circuit complexity and performance requirements. The circuit is then laid out and routed in CAD (computer-aided design) software to ensure signal integrity and optimal electrical performance. During the design process, special attention needs to be paid to the optimization of ground line width, spacing, control impedance, and signal paths to reduce signal loss and crosstalk.

After the layout is completed, electromagnetic field simulation is performed to verify the high-frequency characteristics and anti-interference ability of the design. This helps identify and resolve potential design issues before actual manufacturing. Finally, design reviews and prototype testing are performed to ensure the PCB performs as expected and meets customer requirements.

Why use ceramic Rogers RT/Duroid® 6010 PCB over other boards?

Rogers RT/Duroid® 6010 PCB is a high-performance printed circuit board (PCB) made from a special ceramic material that offers many advantages that make it more suitable than other board materials in specific applications.

First, Rogers RT/Duroid® 6010 PCB provides excellent electrical performance. It has a very low loss factor and a stable dielectric constant, which are critical for high frequency and microwave circuits. This characteristic makes it widely used in wireless communications, radar systems and satellite technology to maintain signal accuracy and stability.

Second, Rogers RT/Duroid® 6010 PCB has excellent thermal stability and thermal conductivity. Ceramic materials themselves have good heat dissipation properties and can effectively disperse and conduct the heat generated in circuits. This makes it perform well in environments with high power density and long operating times, and is less susceptible to performance fluctuations due to temperature changes.

In addition, the mechanical stability of Rogers RT/Duroid® 6010 PCB is excellent. Ceramic materials are stronger and more durable than typical resin substrates and can maintain circuit integrity and reliability in harsh environmental conditions, such as in military applications and aerospace.

Designing and manufacturing the Rogers RT/Duroid® 6010 PCB requires specialized skills and craftsmanship. Advanced CAD design software is typically used for circuit layout, and each step of the manufacturing process is tightly controlled to ensure the final product meets design specifications and customer requirements.

In summary, the choice of Rogers RT/Duroid® 6010 PCB was primarily based on its superior electrical performance, thermal management capabilities and mechanical stability. This makes it an ideal choice for high-frequency, high-speed circuit design, especially for applications that require extremely high signal quality and stability.

What is the Rogers RT/Duroid® 6010 PCB Fabrication Process?

First, choose the right Rogers RT/Duroid® 6010 material. This material is typically supplied in the form of laminated prepregs and has stable dielectric properties and mechanical strength. Before manufacturing begins, materials require pretreatment to ensure surface cleanliness and surface roughness control.

Lamination is one of the core steps in manufacturing Rogers RT/Duroid® 6010 PCB. In this process, pre-treated material layers are solidified into a solid whole using high temperatures and pressures. Control of temperature and pressure during lamination is critical to ensure material uniformity and thickness consistency.

After lamination is complete, holes need to be drilled into the PCB to mount the electronic components and connect the wires. The location and accuracy of drilling directly affects the layout and functionality of the circuit board. For PCBs used in high-frequency applications, drilling accuracy and surface quality requirements are particularly stringent.

The internal and external connections of the PCB require electrical conduction, which requires chemical plating of a copper layer on the hole walls and surface after drilling. This step not only ensures a good electrical connection, but also increases the mechanical strength of the PCB.

Patterning is the process of forming circuit patterns on the surface of a PCB. Through photolithography and chemical etching, the unnecessary copper layer is removed, leaving the wires and pads required for circuit design. This process requires high-precision control and complex processing steps to ensure circuit reliability and performance.

The final step in the PCB is metallization, a process that coats the pads and connections with a protective layer of metal, usually tin or a metal alloy. Not only does this help protect the circuit from the environment and oxidation, it also provides a reliable soldering surface.

Once manufactured, each Rogers RT/Duroid® 6010 PCB undergoes rigorous final inspection. Inspection includes electrical testing, visual inspection and dimensional verification to ensure products meet design specifications and customer requirements.

The manufacturing process of Rogers RT/Duroid® 6010 PCB is a complex and precise process that requires highly specialized equipment and technology to ensure that each PCB reaches optimal levels of electrical performance and mechanical strength.

The application of ceramic Rogers RT/Duroid® 6010 PCB

Rogers RT/Duroid® 6010 PCB, especially when utilizing ceramic materials, finds extensive applications across various high-frequency and high-performance electronic systems. Its unique properties make it indispensable in demanding industries where reliability and performance are critical factors.

One of the primary applications of ceramic Rogers RT/Duroid® 6010 PCB is in communication systems. These PCBs are used in base stations, antennas, microwave links, and satellite communication systems. Their low loss tangent and stable dielectric constant ensure efficient signal transmission and reception, making them ideal for high-frequency applications.

In radar systems and aerospace technology, where precision and reliability are paramount, ceramic Rogers RT/Duroid® 6010 PCBs play a crucial role. They are employed in radar transmitters and receivers, radar signal processing units, as well as in avionics systems. The PCBs’ ability to withstand high temperatures and harsh environmental conditions while maintaining signal integrity is vital for these applications.

Medical electronics benefit greatly from the use of ceramic Rogers RT/Duroid® 6010 PCBs due to their stability and reliability. They are used in medical imaging equipment, such as MRI (Magnetic Resonance Imaging) machines and CT (Computed Tomography) scanners, where precise signal processing and minimal interference are essential for accurate diagnostics.

In the automotive industry, ceramic Rogers RT/Duroid® 6010 PCBs are employed in radar systems for collision avoidance, adaptive cruise control, and autonomous driving features. These PCBs enable reliable and accurate detection of objects and obstacles, contributing to enhanced vehicle safety and performance.

Industrial applications such as industrial automation, robotics, and control systems also benefit from the use of ceramic Rogers RT/Duroid® 6010 PCBs. Their high-frequency capabilities and robust design make them suitable for use in sensors, control units, and data acquisition systems where consistent performance under varying conditions is required.

In conclusion, ceramic Rogers RT/Duroid® 6010 PCBs are pivotal components in advanced electronic systems across multiple industries. Their ability to deliver high performance, reliability, and stability in high-frequency applications makes them an indispensable choice for engineers designing cutting-edge technologies.

FAQs

What frequency ranges are Rogers RT/Duroid® 6010 PCB suitable for?

Rogers RT/Duroid® 6010 PCB is primarily suitable for circuit designs in the high frequency range, typically between a few hundred megahertz to several gigahertz. This makes it particularly suitable for radio frequency (RF) and microwave applications such as the high-performance circuit needs in wireless communications equipment, radar systems and satellite technology.

How is the thermal management of the Rogers RT/Duroid® 6010 PCB?

Rogers RT/Duroid® 6010 PCB material has excellent thermal conductivity and thermal stability, effectively dissipating heat generated in circuits. This characteristic makes it perform well in high power density and long-term operation environments, ensuring circuit operation stability and reliability.

Why Choose Rogers RT/Duroid® 6010 Material Over Other High Frequency Materials?

Rogers RT/Duroid® 6010 material combines low loss, stable dielectric constant and excellent high frequency characteristics, making it outstanding in a variety of high frequency circuit designs. It provides better signal fidelity and transmission efficiency than other materials, making it suitable for applications requiring high performance and reliability.

QYC SUBSTRATE

QYC SUBSTRATE