What is Mitsubishi BT LED PCB?

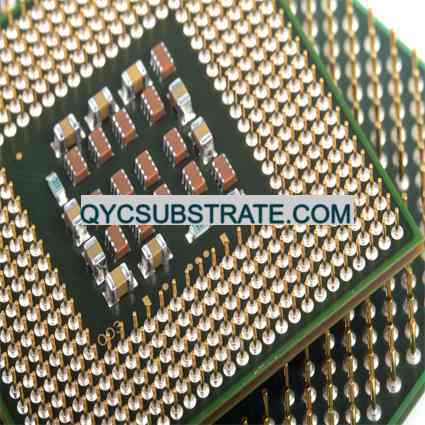

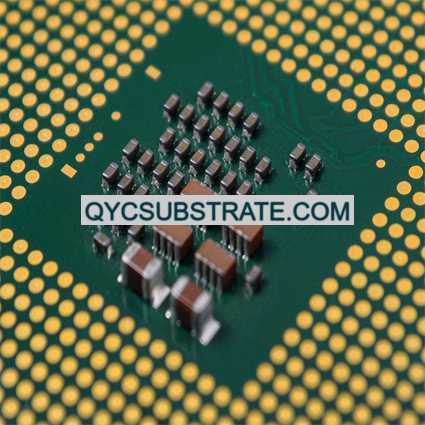

Mitsubishi BT LED PCB Manufacturer.Mitsubishi BT LED PCB Manufacturer specializes in producing high-quality printed circuit boards (PCBs) specifically designed for LED applications. Leveraging advanced manufacturing techniques, Mitsubishi ensures that their BT LED PCBs deliver superior thermal management, reliable performance, and long-term durability. Their commitment to precision and innovation makes them a leading choice for businesses seeking efficient and high-performance PCB solutions for LED lighting systems.

Mitsubishi BT LED PCB is a high-performance LED printed circuit board (PCB) manufactured by Mitsubishi Corporation specifically designed to support a variety of LED lighting applications. BT refers to the highly thermally conductive material used in this PCB, ensuring efficient heat dissipation and long-term stable operation of the LED system. Mitsubishi BT LED PCB is mainly used in high-brightness LED lighting modules, automotive lighting, architectural lighting, industrial lighting and other fields. Its design and manufacturing process fully consider the heat dissipation needs and electrical performance of LEDs.

The types of Mitsubishi BT LED PCB

Aluminum-based LED PCB is a common type, especially suitable for LED lighting applications that require excellent heat dissipation performance. Aluminum-based PCB uses aluminum metal as the substrate material. Its excellent thermal conductivity can effectively conduct heat from the LED chip to the outside of the PCB, thereby reducing the operating temperature of the LED. This type of PCB is particularly suitable for high-power LED lighting modules such as automotive headlights, industrial lamps, and high-power indoor and outdoor lighting.

Mitsubishi BT LED PCB Manufacturer

Copper-based LED PCB uses copper as the substrate material. Compared with aluminum-based PCB, copper-based PCB has higher thermal conductivity. Copper-based PCBs are suitable for high-power LED applications that require extremely high heat dissipation capabilities. Because copper substrates are able to dissipate heat more efficiently, they are often used in high-brightness LED lighting systems, high-frequency applications, and equipment with higher thermal management requirements, such as high-performance laser lights and professional photography lights.

FR-4 based LED PCB is a PCB based on FR-4 material, a common glass fiber reinforced epoxy material suitable for low power LED applications. Although FR-4 has a low thermal conductivity, its excellent electrical performance and cost-effectiveness make it very popular in general LED lighting applications, such as home lighting and commercial lighting. FR-4 based LED PCB is suitable for lower power LED lighting systems and is designed to be flexible to meet a variety of standard lighting needs.

Ceramic-based LED PCB uses ceramic as the substrate material, which has very high thermal conductivity and electrical insulation properties. Ceramic-based PCBs are suitable for applications requiring extremely high thermal management and electrical performance. Because ceramics can maintain stable performance in high-temperature environments, this type of PCB is commonly used in high-power LED lighting fixtures and high-frequency RF applications. Ceramic-based LED PCB also has excellent mechanical strength and chemical corrosion resistance, making it suitable for applications in harsh environments.

Flexible LED PCB is made of flexible materials and can be installed on curved or irregularly shaped surfaces. Flexible LED PCB is suitable for lighting designs that require bending or folding, such as flexible light strips, bendable display panels and creative lighting products. They can adapt to a variety of complex design needs and provide even lighting in small or irregular spaces.

Rigid-flexible combination LED PCB combines the advantages of rigid and flexible PCBs, enabling partially rigid and partially flexible designs to be implemented on one circuit board. This type of PCB is suitable for applications that require flexible layout and structural strength, such as complex lighting fixtures and equipment that need to bend in multiple directions.

Each type of Mitsubishi BT LED PCB has unique advantages and application scenarios, and choosing the right PCB type can optimize the performance and efficiency of your LED lighting system. Depending on the specific application needs, manufacturers and designers can select the most appropriate PCB type to achieve optimal lighting effects and system stability.

The advantages of Mitsubishi BT LED PCB

Mitsubishi BT LED PCBs stand out in the field of LED lighting with their superior performance and high reliability. The following are the main advantages of Mitsubishi BT LED PCB:

Mitsubishi BT LED PCB uses highly thermally conductive substrate materials, such as aluminum substrates or copper substrates, which have excellent thermal conductivity. Good thermal management performance can effectively and quickly dissipate the heat generated by the LED chip to prevent overheating. This not only improves the efficiency of the LED lighting system but also extends the life of the LED components. Compared with traditional PCB materials, BT materials can significantly reduce performance degradation caused by temperature rise.

Mitsubishi BT LED PCB’s design and manufacturing process ensure excellent electrical performance. High-precision circuit patterns and stable electrical connections help reduce signal interference and electrical failures, ensuring the reliability of LED lighting systems. In high-frequency and high-power applications, BT materials excel, delivering current and signals reliably, delivering consistent brightness and performance.

Mitsubishi BT LED PCB manufacturers follow strict quality control standards to ensure that each PCB meets high quality requirements. From material selection to production technology to final testing and inspection, every link is strictly controlled. This ensures long life and high reliability of the PCB, allowing it to operate stably even in harsh working environments.

Mitsubishi BT LED PCB manufacturer offers a variety of design options and customization services to meet different customer needs. Whether it is a complex multi-layer circuit board or a simple single-layer board, manufacturers can design and produce according to specific application requirements. This flexibility makes Mitsubishi BT LED PCB suitable for a variety of lighting solutions, including indoor lighting, automotive lighting, architectural lighting, industrial lighting, etc.

Many Mitsubishi BT LED PCBs feature eco-friendly materials and energy-saving designs that help reduce the environmental impact during production. Efficient thermal management and electrical performance not only help extend equipment life, but also improve overall energy utilization, resulting in higher energy efficiency and lower energy consumption.

Mitsubishi BT LED PCB manufacturers use advanced manufacturing technologies such as precision photolithography, electroless copper plating, and automated assembly, etc. These processes ensure high precision and consistency of PCBs while also improving production efficiency. Modern production equipment and processes can support large-scale production and meet the needs of large-volume orders.

Overall, Mitsubishi BT LED PCB demonstrates significant advantages in thermal management, electrical performance, quality control, design flexibility, and environmental protection and energy saving, making it an ideal choice for LED lighting applications.

How to Design a Mitsubishi BT LED PCB?

Designing a Mitsubishi BT LED PCB involves several key steps to ensure excellent performance and reliability of the final product. The following are the main steps and considerations in the design process:

First, you need to identify your design requirements, including the type of LED, power requirements, application environment, and required thermal management performance. These requirements will impact PCB size, layout, material selection, and manufacturing processes. For example, high-power LEDs may require thicker substrates and increased heat dissipation capabilities.

Mitsubishi BT LED PCB usually uses aluminum substrate or copper substrate, these materials have excellent thermal conductivity. Select the appropriate substrate material based on application requirements:

Aluminum substrate: suitable for most LED lighting applications, with good thermal conductivity and cost-effectiveness.

Copper substrate: Provides higher thermal conductivity, suitable for high-power LED applications.

Use PCB design software such as Altium Designer, Eagle, or KiCad for circuit design. Make sure the design includes:

Current path: Properly plan the current path to reduce resistance and heat generation.

Heat dissipation design: Design heat dissipation holes or heat sinks to ensure that the LED chip can effectively dissipate heat and extend its service life.

Electrical connection: Ensure stable electrical connection to avoid signal interference and electrical faults.

Place LED components in the design software and optimize the layout:

Component layout: Arrange LED chips and other components appropriately based on electrical and thermal management needs.

Wiring design: Use wider wires to lower resistance and reduce heat build-up. Make sure the traces are short and straight to reduce electrical noise and power loss.

Thermal management is a critical factor in LED PCB design. Consider the following design strategies:

Heat dissipation holes: Design heat dissipation holes on the PCB to help heat conduction from the LED chip to the substrate.

Heat sink: Add a heat sink to enhance heat transfer.

Thermal simulation: Use thermal simulation tools to simulate heat distribution and optimize heat dissipation design.

Select the appropriate manufacturing process, including:

Drilling and Plating: Precision drilling is performed and plating is performed to make electrical connections.

Lithography and Etching: Using photolithography techniques to transfer circuit patterns onto a PCB and etching to remove excess copper layers.

Assembly and soldering: Solder the LED chip to the PCB and perform other necessary assembly operations.

After manufacturing is complete, conduct comprehensive testing and verification:

Electrical Test: Check the integrity of electrical connections to ensure there are no shorts or opens.

Thermal testing: Perform thermal testing to verify that the thermal design is effective and ensure that the LED is operating at normal operating temperature.

Ensure designs meet quality control standards, including material quality, manufacturing accuracy and performance stability. Choose a manufacturer with a good reputation for production to ensure the quality of the final product.

Why use ceramic Mitsubishi BT LED PCB over other boards?

Ceramic Mitsubishi BT LED PCBs are an important component in high-performance lighting solutions. Ceramic materials offer significant advantages over traditional PCB materials such as FR-4 or aluminum substrates in a number of ways, allowing them to perform better in high-power and high-temperature applications. Here are a few of the top reasons to choose ceramic Mitsubishi BT LED PCB:

Ceramic substrate materials such as aluminum oxide (Al2O3) or aluminum nitride (AlN) have extremely high thermal conductivity and can conduct heat from the LED chip to the heat sink more effectively than traditional FR-4 materials or aluminum substrates. . This efficient thermal management not only increases the light output of the LED, but also extends its service life and avoids performance degradation or failure due to overheating.

Ceramic materials typically have a low and stable dielectric constant, which helps reduce signal loss and interference. For LED lighting systems with high-frequency and high-speed signals, stable electrical performance means higher signal integrity and more reliable electrical connections. This is particularly important for lighting applications that require high precision and performance.

Ceramic substrates have high mechanical strength and stability. They maintain a low coefficient of thermal expansion even in environments with extreme temperature changes. This stability helps avoid PCB deformation caused by thermal expansion and contraction, ensuring long-term stable operation of the LED assembly.

Ceramic Mitsubishi BT LED PCB performs well in harsh environments due to the high temperature and chemical resistance of the ceramic material. For example, ceramic substrates can effectively maintain their performance and reliability in environments with high temperatures, high humidity, or corrosive substances. This makes them particularly suitable for industrial lighting and applications in special environments.

The high thermal conductivity and excellent electrical properties of ceramic substrates can improve the light output and energy efficiency of LEDs. By effectively managing heat and reducing electrical losses, ceramic Mitsubishi BT LED PCB can provide a brighter light source and higher light efficiency to meet the needs of high-performance lighting.

LED lighting systems using ceramic Mitsubishi BT LED PCBs typically have a longer service life due to the high heat resistance and chemical stability of the ceramic material. This long-term durability not only reduces maintenance and replacement costs, but also improves overall economic benefits.

Ceramic Mitsubishi BT LED PCB offers significant advantages for high-performance LED lighting systems due to its superior thermal management, electrical performance, mechanical stability and reliability compared to other traditional circuit board materials. In situations where high power, high temperature or complex application environments need to be handled, ceramic substrates can effectively improve the overall performance and durability of the system, making them ideal for many high-end lighting solutions.

What is the Mitsubishi BT LED PCB Fabrication Process?

Ceramic Mitsubishi BT LED PCBs are an essential component in high-performance lighting solutions. Ceramic materials offer significant advantages over traditional PCB materials such as FR-4 or aluminum substrates in a number of ways, allowing them to perform better in high-power and high-temperature applications. Here are a few of the top reasons to choose ceramic Mitsubishi BT LED PCB:

Ceramic substrate materials such as aluminum oxide (Al2O3) or aluminum nitride (AlN) have extremely high thermal conductivity and can conduct heat from the LED chip to the heat sink more effectively than traditional FR-4 materials or aluminum substrates. . This efficient thermal management not only increases the light output of the LED, but also extends its service life and avoids performance degradation or failure due to overheating.

Ceramic materials typically have a low and stable dielectric constant, which helps reduce signal loss and interference. For LED lighting systems with high-frequency and high-speed signals, stable electrical performance means higher signal integrity and more reliable electrical connections. This is particularly important for lighting applications that require high precision and performance.

Ceramic substrates have high mechanical strength and stability. They maintain a low coefficient of thermal expansion even in environments with extreme temperature changes. This stability helps avoid PCB deformation caused by thermal expansion and contraction, ensuring long-term stable operation of the LED assembly.

Ceramic Mitsubishi BT LED PCB performs well in harsh environments due to the high temperature and chemical resistance of the ceramic material. For example, ceramic substrates can effectively maintain their performance and reliability in environments with high temperatures, high humidity, or corrosive substances. This makes them particularly suitable for industrial lighting and applications in special environments.

The high thermal conductivity and excellent electrical properties of ceramic substrates can improve the light output and energy efficiency of LEDs. By effectively managing heat and reducing electrical losses, ceramic Mitsubishi BT LED PCB can provide a brighter light source and higher light efficiency to meet the needs of high-performance lighting.

LED lighting systems using ceramic Mitsubishi BT LED PCBs typically have a longer service life due to the high heat resistance and chemical stability of the ceramic material. This long-term durability not only reduces maintenance and replacement costs, but also improves overall economic benefits.

The application of ceramic Mitsubishi BT LED PCB

Ceramic Mitsubishi BT LED PCB, as a high-performance printed circuit board, is widely used in various high-demand LED lighting fields due to its excellent thermal conductivity and electrical performance. The following are the main application areas of ceramic Mitsubishi BT LED PCB and their advantages:

Ceramic Mitsubishi BT LED PCBs are commonly used in high-power LED lighting systems such as industrial lighting, street lighting, and high-brightness fixtures. The ceramic substrate has extremely high thermal conductivity, which can effectively and quickly dissipate the heat generated by the LED chip, thereby preventing overheating and improving the brightness and service life of the LED. The excellent thermal management properties of ceramic materials make them ideal for high-power lighting applications.

In the field of automotive lighting, ceramic Mitsubishi BT LED PCBs are widely used in automotive headlights, taillights, and daytime running lights. Because the ceramic substrate can maintain stable performance under extreme temperature changes, it ensures the reliability of automotive lighting systems under high and low temperature conditions. The high thermal conductivity of ceramics also effectively reduces heat accumulation in automotive lamps, improving safety and durability.

Ceramic Mitsubishi BT LED PCBs are also used in high-end architectural lighting, including commercial buildings, hotels, and luxury residences. Its excellent thermal management and high brightness output can meet the strict requirements for lighting effects in high-end buildings. Ceramic substrates also have good electrical insulation properties and are suitable for high-density, highly integrated lighting designs.

In the field of medical device lighting, the stability and reliability of ceramic Mitsubishi BT LED PCBs make them the material of choice. LED lighting systems require high brightness and precise optical control in medical equipment to ensure clarity and accuracy during surgical and diagnostic procedures. The thermal management capabilities of ceramic substrates ensure the stable performance of these high-precision devices over long periods of use.

In the aerospace field, ceramic Mitsubishi BT LED PCB is used in various aerospace equipment and lighting systems due to its excellent high temperature resistance and high thermal conductivity. Since these environments have extremely high requirements on temperature and thermal management, ceramic substrates can maintain stable performance under extreme conditions and ensure normal operation of equipment.

The applications of ceramic Mitsubishi BT LED PCB are wide and diverse, and its excellent thermal conductivity and stable electrical performance make it excellent in a variety of demanding lighting applications. From high-power lighting to automotive lighting, and from architectural lighting to medical equipment, this PCB delivers superior performance and reliability. Its unique material properties make it a key component in modern high-end LED lighting systems.

FAQs

What are the main features of Mitsubishi BT LED PCB?

Mitsubishi BT LED PCB is known for its excellent thermal management performance, excellent electrical characteristics and high reliability. These PCBs usually use high thermal conductivity materials, such as aluminum substrates or copper substrates, which can effectively dissipate the heat generated by the LED and prevent overheating from damaging the LED components. In addition, Mitsubishi BT’s PCB design ensures stable electrical connections and high-precision circuit patterns, improving the overall performance and durability of the LED lighting system.

What are the application areas of Mitsubishi BT LED PCB?

Mitsubishi BT LED PCB is suitable for a variety of lighting applications, including:widely used in various LED lighting products such as bulbs, spotlights, and light strips.used for car headlights, taillights and interior lighting to improve car appearance and driving safety. Includes indoor and outdoor architectural lighting solutions such as commercial building, residential and landscape lighting.Suitable for high-brightness lighting needs in industrial environments such as factories and warehouses.

Why choose Mitsubishi BT LED PCB?

Reasons for choosing Mitsubishi BT LED PCB include its efficient thermal management, stable electrical performance and reliability. These features make them excellent in a variety of demanding lighting applications, ensuring long life and efficient operation of LED lighting systems.

QYC SUBSTRATE

QYC SUBSTRATE