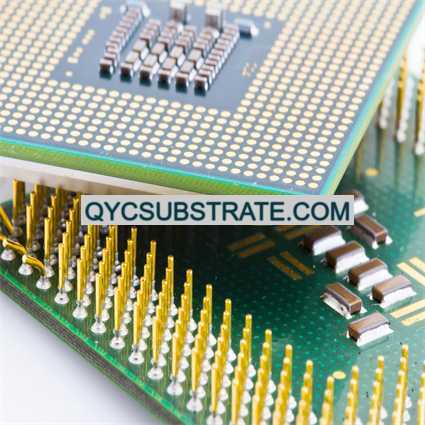

108 Layer PCB Manufacturer.A 108-layer PCB (Printed Circuit Board) manufacturer specializes in producing high-density, multilayer PCBs with 108 distinct layers. These advanced PCBs are used in complex electronic devices requiring exceptional performance, such as high-speed communications equipment, aerospace technology, and advanced computing systems. The manufacturer utilizes cutting-edge technology and precise engineering to ensure reliability, high signal integrity, and durability in their products. Each layer in the PCB serves a specific function, contributing to the overall efficiency and capability of the final electronic device.

What is a 108-Layer PCB?

A 108-layer PCB is a sophisticated type of printed circuit board designed to accommodate complex and high-density electronic systems. This multi-layered board features 108 distinct layers of conductive and insulating materials, stacked together to create a highly intricate circuit structure. Each layer in the PCB is crucial for ensuring that the board can handle a high volume of signals and power distribution while maintaining excellent electrical performance.

108 Layer PCB Manufacturer

The layers typically include alternating sheets of copper (for conducting signals) and dielectric materials (for insulation). The stacking of these layers allows for a compact design that supports a dense arrangement of components and interconnections. This design is particularly beneficial for high-speed and high-performance applications where managing signal integrity and minimizing electromagnetic interference (EMI) are critical.

The Types of 108-Layer PCBs

108-layer PCBs are specialized and can be tailored for various applications based on their design requirements. In high-speed digital applications, these PCBs are used in environments where rapid data transfer and processing are essential, such as in servers and advanced computing systems. The multiple layers help manage high-speed signals effectively, reducing issues like signal degradation and crosstalk.

For RF and microwave applications, the 108-layer PCBs provide excellent performance by incorporating additional layers for shielding and signal integrity. This configuration is essential for maintaining signal quality at high frequencies and minimizing losses.

In power distribution scenarios, 108-layer PCBs handle high current loads and ensure stable power delivery across numerous components. The multiple layers allow for efficient power distribution and help manage voltage drops effectively.

In some cases, hybrid designs are employed, combining traditional PCB features with advanced multi-layer configurations to meet specific needs. These hybrid PCBs can offer a mix of performance characteristics tailored to unique application requirements.

The Advantages of 108-Layer PCBs

The primary advantage of 108-layer PCBs is their ability to support high complexity and density in electronic designs. This feature is crucial for modern devices that require a compact layout without sacrificing functionality. The multiple layers facilitate the routing of numerous signals, power planes, and ground planes, which helps in maintaining signal integrity and managing high-speed data.

Another significant advantage is enhanced thermal management. The multiple layers provide more opportunities for heat dissipation, which is vital in high-power applications where heat buildup could otherwise lead to performance issues.

Design flexibility is also a key benefit. The layered structure allows engineers to integrate complex circuits and multiple functionalities into a single board. This flexibility supports innovative designs and advanced features that are essential for cutting-edge technology.

Moreover, the layered design helps in reducing electromagnetic interference (EMI). The separation of signal layers and the inclusion of shielding layers contribute to minimizing both internal and external EMI, leading to improved overall performance and reliability.

How to Design a 108-Layer PCB

Designing a 108-layer PCB involves several detailed steps to ensure that the board meets all performance and manufacturing requirements. The process begins with defining the application’s specific needs, including electrical, thermal, and mechanical specifications. Understanding these requirements helps in determining the appropriate number of layers and their arrangement.

The next step is to develop a detailed circuit schematic that outlines all components and their connections. This schematic serves as the foundation for creating the PCB layout. Using advanced PCB design software, engineers create a layout that places components and routes traces across the multiple layers.

Defining the layer stack-up is a critical part of the design process. This involves specifying the arrangement and thickness of each layer to optimize signal integrity, thermal management, and overall performance. Design rules and constraints are established to ensure that the layout adheres to manufacturing standards and avoids issues during operation.

Simulation and analysis are performed to verify the design’s performance. This includes checking for signal integrity, thermal behavior, and electromagnetic compatibility. Once the design is finalized, fabrication files are prepared, and the PCB is manufactured. The fabrication process involves material preparation, layer lamination, drilling, etching, plating, and final testing.

Why Use 108-Layer PCBs Over Other Boards?

108-layer PCBs are preferred for applications that require high performance and complex designs due to their advanced capabilities. The high layer count supports greater design complexity, allowing for more components and intricate connections in a compact space.

The enhanced signal integrity and thermal management offered by 108-layer PCBs make them suitable for high-speed and high-power applications. Their design flexibility supports innovative solutions and advanced functionality, making them valuable in cutting-edge technology and demanding electronic systems.

The improved EMI shielding provided by the multiple layers helps maintain performance in sensitive environments, ensuring reliability and stability in various applications.

What is the 108-Layer PCB Fabrication Process?

The fabrication of a 108-layer PCB involves a series of specialized steps. The process starts with material preparation, including the selection and preparation of dielectric layers and copper foils. These materials are then stacked and laminated to form the 108-layer structure.

Drilling and via formation follow, where precise holes are created to establish electrical connections between different layers. The copper layers are then patterned through etching to form the circuit traces, pads, and vias as per the design specifications.

Plating and coating processes are applied to enhance the PCB’s performance and durability. This includes adding surface finishes such as gold or silver to improve solderability and protect the conductive layers. Electrical testing is conducted to verify connectivity and functionality, followed by a final inspection to ensure that the PCB meets all quality and design standards.

The final step involves assembling components onto the PCB and conducting additional testing to confirm that the assembled board performs as expected.

The Application of 108-Layer PCBs

108-layer PCBs are utilized in various advanced and demanding applications. In high-speed computing systems, such as servers and data centers, they support complex circuit designs and high-speed data processing. Their ability to handle dense interconnections and maintain signal integrity is crucial for these environments.

In telecommunications, these PCBs are used in networking equipment and base stations, where high performance and reliable signal transmission are essential. The high layer count supports efficient data transfer and system operation.

Aerospace and defense applications benefit from 108-layer PCBs due to their reliability and performance in extreme conditions. They are used in avionics, satellite systems, and military electronics, where durability and advanced functionality are required.

Medical devices also make use of 108-layer PCBs for advanced diagnostic equipment and imaging systems. The high precision and compact design support the development of sophisticated medical technologies.

In the consumer electronics sector, such as in high-end smartphones and audio equipment, the compact and high-performance characteristics of 108-layer PCBs enable the integration of advanced features into smaller devices.

FAQs

What is a 108-layer PCB?

A 108-layer PCB is a multi-layer printed circuit board with 108 layers of conductive and insulating materials, designed for complex and high-performance electronic systems.

What types of 108-layer PCBs are there?

Types include high-speed digital PCBs, RF and microwave PCBs, power distribution PCBs, and multilayer hybrid PCBs, each tailored for specific performance needs.

What are the advantages of 108-layer PCBs?

Advantages include increased design complexity and density, enhanced signal integrity, improved thermal management, design flexibility, reduced EMI, and reliable performance.

How is a 108-layer PCB designed?

Designing involves defining requirements, creating schematics, designing layouts, defining layer stack-ups, establishing design rules, simulating performance, preparing for fabrication, and conducting testing.

What is the fabrication process for 108-layer PCBs?

The process includes material preparation, layer lamination, drilling, etching, plating, electrical testing, final inspection, and assembly.

QYC SUBSTRATE

QYC SUBSTRATE