What is Rogers RT/duroid® 6002 폴리염화비페?

RT/듀로이드 6002 laminates are low loss materials that provide excellent high frequency performance. With excellent mechanical and electrical properties, these materials are reliable for use in multi-layer board constructions.

기능

- Dielectric constant (디케이) of 2.94 +/- .04

- Low thermal coefficient of Dk at 12 ppm/°C

- 의 발산 계수 .0012 10GHz에서

- 낮은 Z축 열팽창 계수 24 ppm/°C

혜택

- Low loss for excellent high frequency performance

- Tight thickness control

- In-plane expansion coefficient matched to copper

- Low out-gassing; Ideal for space applications

- Excellent dimensional stability

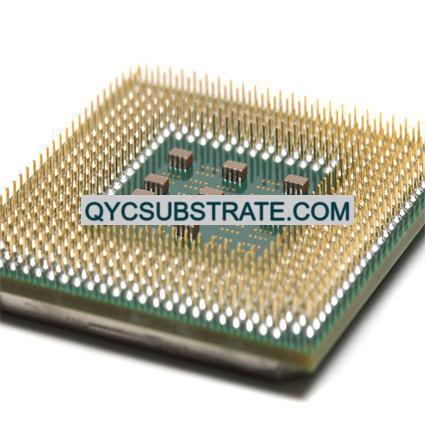

로저스 RT/듀로이드® 6002 PCB 제조업체.Rogers RT/Duroid® 6002 PCB 제조업체는 Rogers RT/Duroid®를 사용하여 고품질 인쇄 회로 기판 생산을 전문으로 합니다 6002 재료. Our expertise lies in crafting PCBs that meet stringent industry standards for performance and reliability.

로저스 RT/듀로이드® 6002 폴리염화비페 is a high-performance printed circuit board (폴리염화비페) made from Rogers Corporation’s RT/Duroid® 6002 재료. This material has excellent electrical and thermal properties and is particularly suitable for high-frequency and high-speed applications. 로저스 RT/듀로이드® 6002 material combines glass fiber reinforced polytetrafluoroethylene matrix and ceramic fillers to provide low dielectric loss, high dielectric constant and excellent thermal stability

The types of Rogers RT/duroid® 6002 폴리염화비페

로저스 RT/듀로이드® 6002 PCB is a multi-functional printed circuit board (폴리염화비페) widely used in high-frequency and 고속 electronic equipment, known for its excellent electrical characteristics and stable performance. Depending on application needs, 로저스 RT/듀로이드® 6002 PCBs can be manufactured in different layer counts and structures to meet a variety of design and performance requirements.

Single-layer Rogers RT/Duroid® 6002 PCB is suitable for simple circuit designs and cost-sensitive applications. It usually consists of a conductor layer and a base material, and has a relatively simple structure and layout. Single-layer PCBs are primarily used for basic circuit designs such as simple antennas, sensor interfaces, and low-complexity control circuits. Due to its simple structure and relatively low manufacturing cost, it is widely used in cost-sensitive products and rapid prototype development.

로저스 RT/듀로이드® 6002 PCB 제조업체

Double and multi-layer Rogers RT/Duroid® 6002 PCBs are better suited for applications requiring more complex circuit layouts and higher levels of integration. They consist of multiple conductor and dielectric layers, allowing designers to implement more complex circuit functions and higher signal density within limited space. This structure enables double- and multi-layer PCBs to support complex signal processing, high-speed data transmission, and precise circuit control.

In the field of communication infrastructure, double- and multi-layer Rogers RT/Duroid® 6002 PCBs are widely used in various RF front-end equipment, base station antennas and signal processing units. These devices require highly integrated circuit boards to ensure efficient signal transmission and processing capabilities. Satellite communications systems also rely on multi-layer PCBs to support complex data processing and communications connections. 또한, pacemakers and MRI equipment in the field of medical equipment often use multi-layer PCB technology to ensure the stability and accuracy of the equipment.

Whether single, dual or multi-layer, 로저스 RT/듀로이드® 6002 PCB maintains the stability of its material properties and superior performance. It has low dielectric loss, high dielectric constant and excellent thermal stability, and is suitable for various high-frequency and high-speed application environments. Its excellent signal integrity and thermal management capabilities make Rogers RT/Duroid® 6002 PCB the first choice for engineers designing complex electronic systems.

요약하면 다음과 같습니다, 로저스 RT/듀로이드® 6002 PCB provides flexible options to accommodate electronic designs of varying complexity and performance requirements. Whether it is a simple circuit layout or a complex high-frequency application, it can provide reliable electrical performance and excellent operating stability.

The advantages of Rogers RT/duroid® 6002 폴리염화비페

로저스 RT/듀로이드® 6002 PCB material has excellent high frequency properties and is suitable for a wide frequency range, from hundreds of megahertz to several gigahertz. This makes it ideal for 5G communications, radio frequency (RF) front-end equipment, and microwave communications systems. The superiority of high-frequency characteristics is reflected in its low transmission loss and excellent signal integrity, which is crucial for applications requiring high-speed data transmission and precision signal processing.

로저스 RT/듀로이드® 6002 PCB material has significantly lower dielectric losses compared to traditional FR-4 board. Low dielectric loss means that the material causes less energy loss during signal transmission, thus maintaining signal clarity and accuracy. This feature makes RT/Duroid® 6002 PCB particularly suitable for applications requiring long-distance transmission and complex signal processing, such as satellite communications and high-speed data network equipment.

로저스 RT/듀로이드® 6002 PCB material has good thermal stability and high thermal conductivity to effectively manage heat in circuits. In environments with high power density and long operation times, stable thermal performance is critical to ensure board reliability and long-term stability. This allows RT/Duroid® 6002 PCB to perform well under a variety of extreme conditions, such as in aerospace equipment, medical equipment and military applications.

우수한 전기적 특성 외에도, 로저스 RT/듀로이드® 6002 PCB material offers superior mechanical and chemical stability. This allows it to maintain good performance in complex operating environments, such as high pressure, high humidity or chemically corrosive environments.

로저스 RT/듀로이드® 6002 PCB material has been widely used around the world and has passed long-term experimental verification and industrial application testing. Its reliability and stability make it the first choice of many leading industry companies, especially in critical applications that require high reliability and excellent performance.

요약하면, 로저스 RT/듀로이드® 6002 PCB material provides strong support for modern high-speed data transmission and precision signal processing with its excellent high-frequency characteristics, low dielectric loss, stable thermal performance and reliable mechanical properties. It has demonstrated excellent performance and wide applicability in both commercial and military applications.

How to Design a Rogers RT/duroid® 6002 폴리염화비페?

첫, engineers needed to learn more about the properties of Rogers RT/Duroid® 6002 재료. This material, composed of a glass fiber reinforced polytetrafluoroethylene matrix and ceramic fillers, has low dielectric loss, high dielectric constant and excellent thermal stability. These characteristics make it superior in high frequency and high speed applications.

During the circuit layout design stage, engineers use professional CAD software to accurately lay out circuit components and wire paths. The key is to ensure that the signal transmission path is as short as possible to reduce transmission loss and delay. 또한, minimizing cross-talk on the circuit board is critical, especially in high-frequency environments where interference can negatively impact signal integrity.

고주파 응용 분야의 특별한 요구 사항을 고려합니다, electromagnetic compatibility (EMC (주)) principles need to be strictly followed during the design process. This includes proper separation of sensitive signal paths and power transmission lines, and the use of grounding and shielding techniques to reduce signal crosstalk and radiated interference. Through reasonable layout and design, the performance stability and reliability of PCB in complex electromagnetic environment can be effectively improved.

Choosing the appropriate manufacturing process is also one of the key factors in a successful design. Surface mount technology (증권 시세 표시기) and multi-layer stacking technology are widely used in the manufacturing of Rogers RT/Duroid® 6002 PCB to ensure the accuracy and reliability of the board. SMT technology allows for higher density component mounting, reducing layout space and increasing circuit board integration. Multi-layer stacking technology allows complex signal interactions and power transmission paths to be implemented in a limited space while maintaining the structural stability of the circuit board.

요약하면 다음과 같습니다, designing a Rogers RT/Duroid® 6002 PCB requires comprehensive consideration of material properties, 회로 레이아웃 최적화, electromagnetic compatibility, and manufacturing processes. Through reasonable design methods and process selection, PCBs can be ensured to operate stably and reliably in high-frequency, high-speed and complex environments, meeting the strict requirements of modern communications and radio frequency applications.

Why use ceramic Rogers RT/duroid® 6002 다른 보드에 PCB?

로저스 RT/듀로이드® 6002 PCB is a specialty material that excels in high frequency and high speed applications. Choosing Rogers RT/Duroid® 6002 boards offers significant advantages over other common PCB materials such as FR-4 boards or other fiberglass reinforced materials.

첫, 로저스 RT/듀로이드® 6002 material has very low dielectric loss. This means that during signal transmission, it can reduce energy loss and maintain signal clarity and integrity. Low-loss characteristics are particularly important for applications that require high-frequency and high-speed data transmission, such as 5G communications, RF front-end equipment, and microwave communication systems. In comparison, traditional FR-4 sheets experience significant signal attenuation at high frequencies, limiting their use in these applications.

Second, 로저스 RT/듀로이드® 6002 PCB material has a stable dielectric constant. This means that the speed and transmission performance of signals as they pass through the circuit board can be more stable and predictable. This stability is critical to ensure accurate signal processing in high-frequency environments, especially in radar systems or satellite communications where precise positioning and timing are required.

또한, 로저스 RT/듀로이드® 6002 material has good thermal conductivity and excellent thermal stability. In electronic devices with high power density and long operation times, effective thermal management can avoid circuit overheating and maintain stable performance. This makes it popular in demanding industrial and military applications such as radar systems, aerospace technology and medical equipment.

마침내, 로저스 RT/듀로이드® 6002 material has a long history of proven use in industrial and commercial applications. Its reliability and stability make it ideal for selecting high-frequency and high-speed applications, not only providing optimized performance during the design phase, but also maintaining long-term reliability in real-world applications.

요약하면 다음과 같습니다, choosing Rogers RT/Duroid® 6002 PCB material over other board materials ensures superior performance and reliability in high-frequency and high-speed electronic designs. Its low loss, stable dielectric constant and excellent thermal management properties make it one of the preferred materials in current and future high-tech applications.

What is the Rogers RT/duroid® 6002 PCB 제조 공정?

The first step in manufacturing a Rogers RT/duroid® 6002 PCB is to prepare the materials and pre-process them. RT/duroid® 6002 materials are typically composed of glass fiber reinforced polytetrafluoroethylene matrix and ceramic fillers. These materials require precise selection and pre-treatment before manufacturing to ensure that their surfaces are smooth and clean for subsequent circuit patterning and laminated.

Circuit design using computer-aided design (CAD) software is a critical step in the manufacturing process. Engineers design circuit patterns on PCB boards based on specific application needs and performance requirements. These designs need to take into account factors such as signal transmission path optimization, wiring optimization, 및 전자기 호환성 (EMC (주)) in high-frequency environments.

Once the circuit pattern design is completed, next comes the lamination and stacking process. 이 단계에서, layers of different materials are stacked together according to the design and high temperatures and pressures are applied to chemically cross-link them and form a strong overall structure. For multi-layer PCB boards, the circuit patterns of each layer need to be accurately aligned to ensure that the final signal transmission path is accurate.

After completing the lamination and stacking, the next step is to drill holes in the PCB board. These drilled holes will be used to connect circuits between different layers and where to mount components. The drilled holes are then chemically plated with copper to form a conductive path and ensure the reliability and stability of signal transmission.

During the final stages of circuit board manufacturing, metallization and surface treatment are performed. The process of metallization involves coating the conductive paths and welding areas with metal to provide good welding properties and conductivity. Surface treatment involves applying a protective coating to the entire PCB surface to prevent oxidation and environmental corrosion, thereby extending the life and stability of the PCB.

Quality control and testing are integral steps throughout the manufacturing process. The electrical and mechanical performance of each Rogers RT/duroid® 6002 PCB is ensured to meet design requirements and industry standards through the use of advanced test equipment and techniques such as probe testing and optical inspection. Only by passing strict quality control testing can the reliability and stability of PCB be guaranteed.

Through these steps, Rogers RT/duroid® 6002 PCB can achieve its excellent high-frequency characteristics, low dielectric loss and stable thermal performance. It is widely used in high-frequency communications, 레이더 시스템, 의료 장비 및 기타 분야, and provides the basis for modern electronic technology. Provide critical support and foundation.

The application of ceramic Rogers RT/duroid® 6002 폴리염화비페

로저스 RT/듀로이드® 6002 PCB는 인쇄 회로 기판입니다. (폴리염화비페) specially designed for high-frequency and high-speed electronic equipment. Its excellent performance makes it widely used in various critical fields. Here are its main applications in different industries:

In modern communication infrastructure, circuit boards are required to transmit signals stably and efficiently to support data transmission and communication connections. The low dielectric loss and high dielectric constant of Rogers RT/Duroid® 6002 PCB make it ideal for use in devices such as wireless base stations, fiber optic communications equipment, and network routers. It can maintain signal integrity in complex electromagnetic environments and ensure the reliability and stability of communication systems.

Satellite communication systems require electronic equipment that can operate stably for a long time in extreme environments. 로저스 RT/듀로이드® 6002 PCB’s high temperature tolerance and excellent thermal conductivity make it the first choice for satellite payloads and ground control systems. It can provide reliable signal transmission and data processing capabilities in the high radiation and temperature change environment in space, ensuring the efficient operation of satellite communications.

Radar systems are critical for fast and accurate signal processing, 특히 군사 및 민간 응용 분야에서. The high-frequency characteristics and stability of Rogers RT/Duroid® 6002 PCB enable the design of radar antenna arrays, signal processing units and data transmission modules. Its low loss and excellent signal transmission performance ensure that the radar system is highly accurate and reliable when detecting and tracking targets.

In medical equipment, such as medical imaging systems, monitoring instruments, and laser therapy equipment, electronic circuits are required to work stably and transmit data accurately. The stability and reliability of Rogers RT/Duroid® 6002 PCB enable it to meet the stringent requirements of high frequency and high-speed data processing in medical equipment. It is capable of operating for extended periods of time in a hospital environment while maintaining circuit accuracy and performance stability.

The aerospace field has extremely high requirements for the reliability and durability of electronic equipment. 로저스 RT/듀로이드® 6002 PCB is widely used in flight control systems, navigation instruments and communications equipment in aerospace applications. Its vibration resistance, radiation resistance and high temperature resistance enable it to provide stable signal processing and data transmission capabilities in extreme environments, ensuring flight safety and the reliability of communication connections.

요약하면 다음과 같습니다, 로저스 RT/듀로이드® 6002 PCB has become an indispensable part of various high-frequency and high-speed electronic equipment due to its excellent high-frequency characteristics, 저손실 및 안정적인 열 성능. Its wide application in communications, 항공 우주, medical and military fields ensures the reliability and performance superiority of these critical systems.

자주 묻는 질문(FAQ)

Rogers RT/Duroid®의 주파수 범위는 무엇입니까? 6002 에 적합한 PCB?

로저스 RT/듀로이드® 6002 PCB is designed for a wide range of high frequency applications, typically covering the frequency range from a few hundred megahertz to several gigahertz. This makes it particularly suitable for 5G communications, radio frequency front-end equipment, microwave communication systems and other application scenarios that require high-frequency transmission and precise signal processing. The superior electrical characteristics and stability of Rogers RT/Duroid® 6002 PCB ensure excellent performance in these high-speed data transmission environments.

Rogers RT/Duroid®의 열 관리는 어떻습니까? 6002 폴리염화비페?

로저스 RT/듀로이드® 6002 PCB material has excellent thermal conductivity and thermal stability to effectively manage heat in circuits. 따라서 높은 전력 밀도와 긴 작동 시간이 필요한 응용 분야에 특히 적합합니다. 고주파 및 고속 회로에서, heat buildup can have a negative impact on signal stability and circuit life. 그러므로, the good thermal management capabilities of Rogers RT/Duroid® 6002 PCB help maintain device reliability and stability.

Why choose Rogers RT/Duroid® 6002 material over other high frequency materials?

로저스 RT/듀로이드® 6002 material combines excellent electrical properties with stable mechanical properties to perform well in high-frequency environments. FR-4 보드와 같은 기존의 유리 섬유 강화 보드보다 유전 손실이 낮고 신호 무결성이 우수합니다, making it suitable for demanding RF and microwave circuit designs. 또한, 로저스 RT/듀로이드® 6002 PCB material has long proven reliability and stability in a wide range of industrial and commercial applications.

QYC 기판

QYC 기판