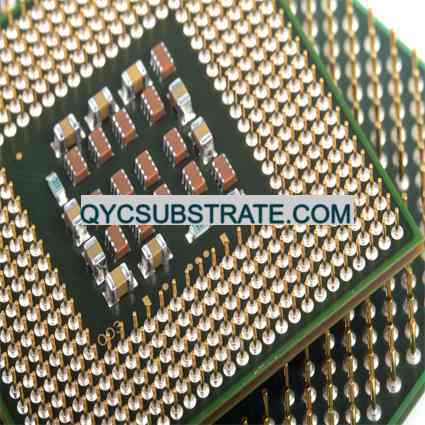

What is Mitsubishi Series PCB/BGA Substrate?

Mitsubishi Series PCB/BGA Substrate Manufacturer.Mitsubishi Series PCB/BGA Substrate Manufacturer is a leading provider of high-quality substrates, specializing in advanced PCB and BGA solutions. Known for their precision engineering and innovative technology, Mitsubishi ensures superior performance and reliability for various electronic applications, from consumer electronics to high-performance computing. Their substrates are designed to meet stringent industry standards, providing excellent thermal management, 신호 무결성, and mechanical stability. Mitsubishi’s commitment to excellence makes them a trusted partner in the electronics manufacturing industry.

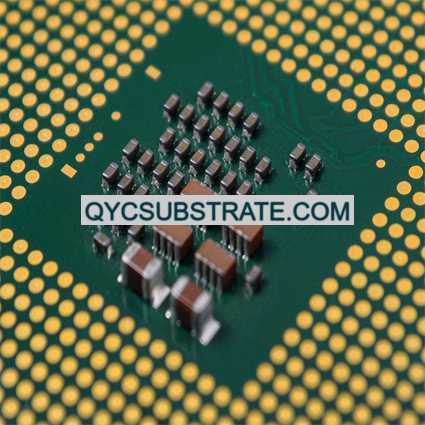

Mitsubishi Series PCB/BGA Substrate refers to a range of high-performance printed circuit board (폴리염화비페) materials and ball grid array (BGA) substrates developed by Mitsubishi. These materials are engineered to meet the demands of advanced electronic applications, offering superior electrical and mechanical properties. The Mitsubishi Series PCB/BGA substrates are known for their excellent thermal performance, high reliability, and ability to support high-density interconnects (HDI는).

미쓰비시 시리즈 PCB/BGA 기판 제조업체

These substrates are commonly used in various high-end applications, including telecommunications, automotive electronics, 항공 우주, 그리고 소비자 전자공학. They provide the necessary performance characteristics to handle the complexities of modern electronic devices, ensuring robust and reliable operation even in challenging environments.

The Types of Mitsubishi Series PCB/BGA Substrates

Mitsubishi offers a variety of PCB/BGA substrate types to cater to different application needs:

These laminates feature a high glass transition temperature (안내), making them suitable for applications that require excellent thermal stability and reliability under high temperatures. They are often used in automotive and aerospace electronics.

These materials have low dielectric constant (디케이) and dissipation factor (디에프), 신호 손실을 최소화하고 높은 신호 무결성을 보장합니다.. They are ideal for high-frequency and high-speed digital applications, such as telecommunications and data processing.

Environmentally friendly and compliant with global regulations, these laminates are free from halogenated flame retardants. They are used in consumer electronics and other applications where environmental considerations are important.

Designed for applications that generate significant heat, these laminates offer excellent thermal conductivity to efficiently dissipate heat. They are used in power electronics and LED lighting systems.

These laminates combine flexibility and rigidity, providing design versatility for applications requiring both dynamic and static sections, such as wearable electronics and advanced medical devices.

The Advantages of Mitsubishi Series PCB/BGA Substrates

Mitsubishi Series PCB/BGA substrates offer several key advantages that make them suitable for a wide range of applications:

These substrates can withstand high temperatures without degrading, ensuring reliable performance in thermally challenging environments.

The low dielectric constant and dissipation factor of these materials ensure minimal signal loss and high signal fidelity, which is crucial for high-frequency and high-speed digital applications.

Mitsubishi substrates provide excellent mechanical strength and chemical resistance, 혹독한 환경에서도 장기적인 신뢰성과 내구성 보장.

Halogen-free laminates comply with environmental regulations, making them suitable for applications where sustainability is a priority.

The availability of various types, including high-Tg, low-Dk, low-Df, high thermal conductivity, flexible, and rigid-flex laminates, offers designers the flexibility to choose the best material for their specific application requirements.

How to Design a PCB with Mitsubishi Series Substrates?

Designing a PCB with Mitsubishi Series substrates involves several critical steps to ensure optimal performance:

Choose the appropriate Mitsubishi substrate material based on the application requirements, considering factors such as thermal performance, 신호 무결성, and environmental compliance.

신호 무결성을 보장하기 위해 전송 라인의 임피던스를 정밀하게 제어. Use electromagnetic simulation software to model and verify the impedance of PCB traces.

고주파 신호 경로의 길이를 최소화하여 신호 손실 및 간섭 감소. 누화 및 전자기 간섭을 최소화하기 위해 고속 차동 신호에 차동 쌍 라우팅을 사용합니다..

안정적인 작동을 보장하고 소음을 최소화하기 위해 견고한 접지 및 배전 네트워크를 설계하십시오.. 접지면을 활용하여 복귀 전류에 대한 저임피던스 경로 제공.

효과적인 열 관리 전략 통합, 열 비아 및 방열판과 같은, 고출력 부품에서 발생하는 열을 발산하고 안정적인 작동을 유지합니다..

PCB 설계가 표준 제조 공정과 호환되는지 확인. Collaborate closely with the PCB manufacturer to confirm design parameters and fabrication capabilities.

Why Use Mitsubishi Series PCB/BGA Substrates Over Other Boards?

Using Mitsubishi Series PCB/BGA substrates offers several benefits over traditional PCB materials:

The low dielectric constant and low dissipation factor of Mitsubishi substrates ensure superior signal integrity and minimal signal loss, which is essential for high-frequency and high-speed digital applications.

Mitsubishi substrates can withstand high temperatures without degrading, making them ideal for applications that experience significant thermal stress.

These substrates provide excellent mechanical strength and chemical resistance, ensuring long-term reliability and durability in harsh environments.

Halogen-free laminates meet global environmental regulations, making them suitable for applications where sustainability is a priority.

Mitsubishi substrates support various configurations, including high-Tg, low-Dk, low-Df, high thermal conductivity, flexible, and rigid-flex designs, offering greater design flexibility and optimization.

What is the Mitsubishi Series PCB/BGA Substrate Fabrication Process?

The fabrication process of Mitsubishi Series PCB/BGA substrates involves several precise steps to ensure high performance and reliability:

Select and prepare the substrate material according to design specifications. 재료를 필요한 치수로 절단하고 오염 물질을 제거하기 위해 청소해야 합니다.

다층 PCB용, 고온 및 고압에서 개별 층을 함께 적층합니다.. 층의 적절한 정렬과 접착을 보장합니다..

설계 레이아웃에 따라 바이어스 및 구성품 리드를 위한 구멍을 뚫습니다.. 정밀 드릴링은 고주파 신호의 무결성을 유지하는 데 필수적입니다.

드릴 된 구멍과 비아를 구리로 도금하여 층 사이에 전기 연결을 만듭니다.. 이 단계는 신뢰할 수 있는 신호 전송과 기계적 안정성을 보장합니다.

Use photolithography to transfer the circuit pattern onto the substrate material. 이 공정에는 감광성 필름으로 재료를 코팅하는 것이 포함됩니다, 마스크를 통해 자외선에 노출시키는 경우, 패턴을 개발하는 것입니다.

원하지 않는 구리를 에칭하여 원하는 회로 패턴을 드러냅니다.. 이 단계는 정확하고 깨끗한 추적을 보장하기 위해 정밀한 제어가 필요합니다.

표면 마감 적용, ENIG와 같은 (무전해 니켈 침지 금) 또는 HASL (뜨거운 공기 솔더 레벨링), 구리 흔적을 보호하고 우수한 납땜성을 보장합니다..

PCB의 성능과 품질을 확인하기 위해 전기 테스트 및 육안 검사를 수행합니다.. 여기에는 임피던스 제어 확인이 포함됩니다, 신호 무결성, 및 전반적인 기능.

The Application of Mitsubishi Series PCB/BGA Substrates

Mitsubishi Series PCB/BGA substrates are used in various high-end applications due to their superior performance and reliability:

These substrates are extensively used in wireless communication systems, 휴대전화 포함, 기지국, 및 위성 통신. 이를 통해 고속 데이터 전송과 효율적인 신호 처리가 가능합니다.

Mitsubishi substrates are used in advanced driver-assistance systems (ADAS (장애인)), 레이더 센서, 현대 차량의 고속 데이터 통신. 혹독한 자동차 환경에서 안정적인 작동을 보장합니다.

These substrates are used in radar systems, 위성 항법, 항공 우주 산업의 통신 장치. 뛰어난 열 안정성과 신뢰성은 극한 환경에서 최적의 성능을 보장합니다..

Mitsubishi substrates are used in high-performance consumer electronics, such as smartphones, tablets, and wearable devices, ensuring reliable operation and high signal integrity.

These substrates are used in advanced medical devices that require high reliability and precision, such as imaging systems and diagnostic equipment.

자주 묻는 질문(FAQ)

What are the main advantages of Mitsubishi Series PCB/BGA substrates?

The main advantages include high thermal stability, superior signal integrity, enhanced reliability, environmental compliance, and design versatility.

What application areas are suitable for Mitsubishi Series PCB/BGA substrates?

Mitsubishi Series substrates are suitable for telecommunications, automotive electronics, 항공 우주, consumer electronics, and medical devices, 그 중에서도.

What is the difference between Mitsubishi Series substrates and traditional PCB materials?

Mitsubishi Series substrates offer better signal performance, higher thermal stability, and improved reliability in high-frequency and high-speed applications compared to traditional PCB materials, which are typically used for lower frequency and less demanding applications.

What factors should be considered when designing a PCB with Mitsubishi Series substrates?

고려해야 할 요소에는 재료 선택이 포함됩니다, 임피던스 제어, 신호 경로 레이아웃, 접지 및 전원 평면, 열 관리, 및 제조 가능성.

QYC 기판

QYC 기판