What is Mitsubishi BT PCB?

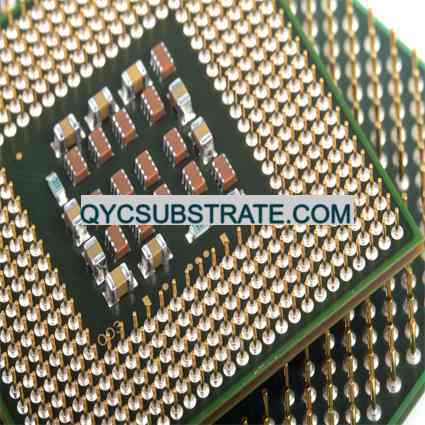

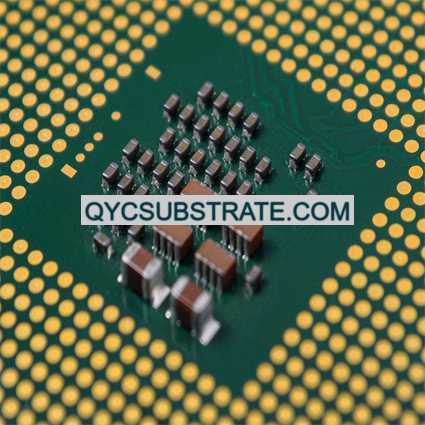

Mitsubishi BT PCB Manufacturer.Mitsubishi BT PCB Manufacturer is a leading provider of high-quality printed circuit boards (PCB (폴리염화비페닐)), renowned for its advanced technology and precision. Specializing in BT (bismaleimide-triazine) PCB (폴리염화비페닐), Mitsubishi offers exceptional thermal performance and reliability, crucial for high-speed and high-frequency applications. Their expertise ensures durable, high-performance solutions tailored to various industries, including automotive, telecommunications, 그리고 소비자 전자공학. With cutting-edge manufacturing processes and a commitment to innovation, Mitsubishi BT PCB Manufacturer stands out in delivering robust, high-quality PCBs that meet the rigorous demands of modern electronic devices.

Mitsubishi BT PCB is a high-performance printed circuit board (폴리염화비페) offered by Mitsubishi Electric to meet the needs of a variety of electronic equipment and industrial applications. BT stands for “Bismaleimide-Triazine,” a resin material used in manufacturing high-performance PCBs. Mitsubishi BT PCBs incorporate this material to achieve superior electrical performance and durability, especially for demanding environments and applications.

These features make it ideal for high frequency, high power and high temperature environments. 또한, Mitsubishi Electric’s extensive experience and advanced manufacturing processes ensure the quality and reliability of PCB (폴리염화비페닐), enabling them to meet the stringent requirements of a variety of applications.

The types of Mitsubishi BT PCB

Mitsubishi BT 폴리염화비페 manufacturer offers many types of Printed Circuit Boards (PCB (폴리염화비페닐)) 다양한 응용 프로그램의 요구 사항을 충족시키기 위해. The following is an introduction to the main types:

Aluminum base PCBs are an important product from Mitsubishi BT and are particularly suitable for applications requiring efficient heat dissipation. The aluminum substrate provides excellent thermal conductivity, which can quickly dissipate the heat generated by LEDs or other high-power components, thereby reducing the impact of overheating on the circuit. This type of PCB is widely used in LED lighting, automotive lighting, and high-power electronics.

미쓰비시 BT PCB 제조업체

High frequency PCBs are designed for radio frequency (RF) and microwave applications. Mitsubishi BT’s high-frequency PCBs use low dielectric loss materials such as PTFE (polytetrafluoroethylene) or other high-performance insulating materials that reduce signal attenuation and interference during high-frequency signal transmission. High-frequency PCBs are commonly used in areas such as wireless communications, 레이더 시스템, and satellite communications equipment.

Multilayer PCBs have multiple circuit layers that enable complex circuit designs by stacking multiple insulating layers. This type of PCB is suitable for applications requiring high-density circuit layout, such as computer motherboards, communications equipment, and complex electronic control systems. Mitsubishi BT’s multi-layer PCB provides higher integration and more functionality while maintaining good electrical performance and reliability.

Ceramic PCBs are another important type of high-performance circuit board, especially suitable for high-temperature and high-power applications. Ceramic substrates provide excellent thermal conductivity and mechanical strength, enabling stable operation in extreme environments. Mitsubishi BT’s ceramic PCBs are commonly used in high-power amplifiers, radio frequency circuits and medical equipment. Its stable electrical performance and high temperature resistance make it excellent in demanding applications.

A flexible PCB is a circuit board that can bend and fold, making it suitable for applications where space is limited or where dynamic bending is required. Mitsubishi BT’s flexible PCBs can be used in a variety of consumer electronics, portable devices, and medical devices. This PCB provides greater design flexibility and higher reliability, able to adapt to complex shapes and dynamic environments.

Rigid flexible PCB combines the advantages of rigid PCB and flexible PCB, providing both rigid support and flexible bending capabilities. This type of PCB is suitable for applications that require mounting and connecting multiple components in space-constrained environments, such as mobile devices and complex electronic modules. Mitsubishi BT’s rigid-flex PCBs offer high reliability and design flexibility adapted to the needs of modern electronics.

These PCB types demonstrate Mitsubishi BT’s manufacturing expertise in different areas, whether it is high power, RF, high frequency or flexible design needs, you can find the right solution. If you need more information or specific technical details, please feel free to contact me!

The advantages of Mitsubishi BT PCB

Mitsubishi BT PCBs are known for their superior electrical performance. These PCBs feature high-quality substrate materials that provide stable dielectric constant and low dielectric loss. This is crucial for high-frequency and high-speed signal transmission, ensuring signal clarity and stability and reducing signal interference and loss. In high-frequency applications, such as radio frequency (RF) and microwave equipment, Mitsubishi BT PCBs ensure reliable data transmission and optimized performance.

Mitsubishi BT PCBs have excellent thermal conductivity properties, especially when using aluminum or copper substrates. This highly thermally conductive material effectively conducts heat generated by electronic components away, preventing overheating from affecting PCBs and other components. Good thermal management not only improves component durability, but also improves overall system stability and reliability. The thermal management benefits of Mitsubishi BT PCBs are particularly evident in high-power applications or demanding environments.

Mitsubishi BT PCBs are known for their high reliability and durability. Strict quality control and advanced manufacturing processes ensure the consistency and long life of each PCB. Whether exposed to extreme temperature changes, vibration, or other demanding environments, Mitsubishi BT PCBs maintain stable performance. This high reliability has made it widely recognized and used in various critical applications.

Mitsubishi BT PCBs offer a high degree of design flexibility to meet the needs of a variety of different applications. Manufacturers are able to create custom designs based on customers’ specific requirements, including multi-layer circuit boards, different types of substrate materials and special circuit layouts. This flexibility allows Mitsubishi BT PCBs to adapt to a wide range of applications from consumer electronics to industrial equipment.

Mitsubishi BT PCB manufacturers use advanced production equipment and technology, including processes such as photolithography, 드릴링, electroplating and assembly. These technologies ensure high-precision circuit patterns and stable electrical performance. Through continuous technological innovation and process improvement, manufacturers are able to provide high-quality products that meet the latest market demands.

Mitsubishi BT PCB manufacturer provides comprehensive customer service and technical support to help customers solve problems throughout the design and production process. Whether it is product consultation, design optimization or after-sales service, manufacturers are committed to providing efficient solutions to meet customer needs.

Despite the very high quality of Mitsubishi BT PCBs, the solutions they offer are still competitively cost-effective. By optimizing production processes and material selection, manufacturers can control costs while maintaining high quality, providing cost-effective PCB solutions.

How to Design a Mitsubishi BT PCB?

Designing Mitsubishi BT PCBs (Printed Circuit Boards) requires several factors to be considered to ensure that the final product excels in performance, reliability and manufacturing processes. Here are the main steps to follow during the design process:

첫, the design requirements of the PCB need to be clarified, including electrical performance, size, number of layers and other special requirements. 예를 들어, determine the required signal frequency, current-carrying capabilities, and thermal management needs. These requirements will affect material selection, 스택업 구조(stack-up structure), and wiring design.

Mitsubishi BT PCB manufacturers offer various material options such as aluminum substrates, ceramic substrates or high frequency materials. Selecting the appropriate substrate material is critical to meeting design requirements. 예를 들어, aluminum substrates are suitable for high-power applications, while ceramic substrates are suitable for high-temperature and high-power environments. Make sure the chosen material has good thermal conductivity and electrical properties.

Create the circuit diagram using PCB design software such as Altium Designer, Eagle, or KiCad. Circuit diagrams are the basis of PCB design and need to accurately represent all electronic components and their connections. Ensure that every component and connection in the circuit diagram meets electrical specifications and is functionally verified.

In PCB design software, design the PCB layout based on the circuit diagram. This includes placing electronic components, routing them, and defining power and ground planes. Keep signal lines as short as possible to avoid interference and optimize signal integrity. Set up proper routing rules for high-frequency signals and power lines to reduce electromagnetic interference (이엠아이).

Especially in high-power applications, thermal management is critical. Thermal diffusion paths need to be considered during design to ensure that heat can be effectively dissipated from high-power components. Use appropriate heat sinks, thermal pads or aluminum substrates to improve thermal management efficiency. Conduct thermal simulation analysis to predict and optimize PCB thermal performance.

After completing the design, conduct Design Rule Check (DRC) and Electrical Rule Check (ERC) to ensure there are no design errors. Use simulation tools to simulate circuit performance to verify signal integrity and electrical characteristics. Check the PCB layout for consistency with the schematic to ensure the design complies with specifications.

Once the design is complete, files for production are generated, including Gerber files, drill files, and assembly drawings. These files will be provided to the PCB manufacturer for actual production and assembly.

Choose an experienced Mitsubishi BT PCB manufacturer that provides the manufacturing capabilities and technical support you need. Communicate design documents with manufacturers to confirm manufacturing processes, materials and production times. Make sure the manufacturer can meet your quality requirements and delivery deadlines.

Upon receipt of the finished PCB, complete testing and verification is performed, 전기 포함, 열, and functional testing. Ensure that the final product meets the design requirements and performs stably in actual applications.

By following the above steps, you can ensure that you design a high-quality Mitsubishi BT PCB that meets the needs of your specific application and remains efficient and reliable during manufacturing.

Why use ceramic Mitsubishi BT PCB over other boards?

Ceramic Mitsubishi BT PCBs offer unique advantages over other types of PCBs in many applications, especially in high temperature, high power and high frequency environments. Here are the top reasons to choose ceramic Mitsubishi BT PCB:

Ceramic materials have very high thermal conductivity and can effectively dissipate heat away from electronic components. For high-power applications and electronic devices that require good heat dissipation, the superior thermal management capabilities of ceramic Mitsubishi BT PCBs can prevent overheating, thereby increasing system stability and longevity. In comparison, traditional FR-4 materials have low thermal conductivity, which can lead to heat build-up and performance degradation.

Ceramic Mitsubishi BT PCBs provide excellent electrical performance, especially in high-frequency and high-speed signal transmission. Ceramic materials have low dielectric loss and stable dielectric constant, which help reduce signal attenuation and interference and ensure the stability and accuracy of signal transmission. This is particularly important for demanding radio frequency (RF) and microwave applications, where other common PCB materials may not meet these high-performance requirements.

Ceramic materials can withstand extreme temperature changes and are suitable for applications in high temperature environments. Ceramic Mitsubishi BT PCB maintains stable performance at high temperatures without causing expansion or contraction of the material due to temperature changes. This makes ceramic PCBs particularly suitable for high-temperature environments and high-power applications such as automotive electronics, industrial equipment, and aerospace.

The ceramic material itself has high mechanical strength and wear resistance, which means that ceramic Mitsubishi BT PCB can maintain good structural stability under physical shock and vibration. Compared to flexible or thinner PCBs, ceramic PCBs are better able to withstand harsh usage conditions and reduce the risk of mechanical damage.

Ceramic Mitsubishi BT PCBs typically have a longer service life due to the stability and durability of the ceramic material. They maintain good performance over long periods of operation and under high load conditions, reducing maintenance costs associated with frequent PCB replacements.

Ceramic materials are highly resistant to chemicals and can remain stable in corrosive environments. This makes ceramic Mitsubishi BT PCBs suitable for use in applications in harsh environments, such as in chemical industry and pharmaceutical equipment, avoiding performance degradation or failure due to chemical corrosion.

전반적, ceramic Mitsubishi BT PCBs offer advantages unmatched by other PCB materials through their superior thermal management, electrical performance, temperature resistance, mechanical strength, longevity and resistance to chemical corrosion. Ceramic PCBs are an ideal choice in applications that require high performance and reliability.

What is the Mitsubishi BT PCB Fabrication Process?

A significant advantage of ceramic Mitsubishi BT PCBs is their excellent thermal conductivity. Ceramic materials have extremely high thermal conductivity and can effectively conduct heat away from electronic components, thereby preventing the impact of overheating on electronic equipment. Compared to traditional FR-4 or aluminum substrates, ceramic PCBs are better suited for applications in high-power and high-temperature environments because they manage heat better, reducing the negative impact of temperature on performance.

Ceramic material has an extremely low coefficient of thermal expansion, which means it does not undergo significant dimensional changes when the temperature changes. This stability helps maintain circuit accuracy and reliability, reducing problems with circuit board deformation or signal distortion caused by temperature changes. As a result, ceramic Mitsubishi BT PCBs are able to maintain stable performance in extreme environments and are particularly suitable for applications requiring high reliability, such as aerospace and military equipment.

Ceramic PCBs offer excellent electrical properties, including low dielectric constant and low dielectric loss. This makes it excellent in high-frequency applications, able to efficiently transmit signals without significant signal loss or delay. This is particularly important for radio frequency (RF) and microwave applications, as these areas require circuit boards to maintain high accuracy and low loss in high-frequency signal transmission.

Ceramic materials are more resistant to chemicals, and ceramic PCBs perform better in corrosive environments than some plastic substrates. This property makes ceramic PCBs suitable for applications that may be exposed to chemicals or harsh environments, such as industrial manufacturing and automotive electronics.

Ceramic PCB is able to withstand higher power densities due to its excellent thermal conductivity. This is particularly important in applications where high-power components need to be operated in a limited space. 예를 들어, in high-power amplifiers and high-speed computing equipment, ceramic PCBs can effectively dissipate heat, ensuring device stability and long-term reliability.

Mitsubishi BT’s ceramic PCBs offer high design flexibility and can be customized to specific application needs. Whether it’s a complex multi-layer design or special thermal management requirements, ceramic PCBs can meet these needs. Manufacturers can tailor PCB construction and materials to customer requirements for optimal performance and functionality.

While the initial cost of ceramic PCBs may be higher, their long life and low maintenance requirements can reduce overall costs over the long term. Due to their high durability and stability, ceramic PCBs require less frequent replacement and lower maintenance costs, making them more cost-effective in the long term.

The application of ceramic Mitsubishi BT PCB

Ceramic Mitsubishi BT PCB is a high-performance printed circuit board (폴리염화비페) based on ceramic materials, which is widely used in a variety of high-demand fields. Its superior electrical performance and thermal management capabilities make it excellent in several major applications:

The high thermal conductivity of ceramic PCBs makes them ideal for high-power electronics. 예를 들어, in power amplifiers and high-power LED lighting systems, ceramic PCBs can effectively dissipate generated heat away from electronic components, preventing performance degradation or equipment failure due to overheating. This excellent thermal management capability ensures the stability and reliability of the equipment and improves the overall efficiency of the system.

In radio frequency (RF) and microwave applications, signal transmission and processing require highly stable dielectric materials. Ceramic Mitsubishi BT PCB provides low dielectric loss and stable dielectric constant, which is crucial for the transmission of high-frequency signals. They are often used in radio frequency modules, microwave circuits and antenna systems to ensure efficient signal transmission and low signal loss.

Medical electronic equipment has extremely high requirements on the stability and reliability of circuit boards. The high reliability and excellent thermal management properties of ceramic Mitsubishi BT PCBs make them ideal for use in critical components in medical devices such as pacemakers, medical imaging equipment, and monitoring instruments. Its excellent insulation performance and high temperature resistance also ensure the stability of the equipment in long-term use.

In the aerospace and military fields, equipment needs to work reliably in extreme environments. Ceramic PCB’s high temperature resistance and excellent electrical properties make it an ideal choice in these areas. Whether in spacecraft electronics or military radar systems, ceramic PCBs can provide the necessary stability and reliability to cope with harsh operating conditions and high-frequency signal processing needs.

With the development of high-frequency communication technology, the requirements for PCB are becoming higher and higher. Ceramic Mitsubishi BT PCBs meet these needs, with their low-loss dielectric properties and high stability making them excellent in high-frequency communications equipment. 예를 들어, in base station equipment and high-speed data transmission systems, the use of ceramic PCBs can significantly improve the quality of signal transmission and the overall performance of the system.

Ceramic Mitsubishi BT PCBs are the solution of choice in many demanding applications due to their excellent thermal conductivity, electrical performance and reliability. Its wide range of applications, from high-power electronics to radio frequency and microwave applications, to medical electronics and aerospace, demonstrate its importance in modern electronic technology. Choosing ceramic PCB can significantly improve the stability and performance of the system and meet the needs of various extreme conditions.

자주 묻는 질문(FAQ)

What is a Mitsubishi BT PCB?

Mitsubishi BT PCB is a printed circuit board (폴리염화비페) that utilizes Mitsubishi’s advanced materials technology. It is designed for high-frequency and high-speed electronic applications. This PCB offers superior electrical performance, 열 관리, and stability, making it suitable for use in communications, automotive, 의료 기기, and other demanding environments.

What is the manufacturing process for Mitsubishi BT PCBs?

The manufacturing process for Mitsubishi BT PCBs includes several steps: material preparation, circuit pattern printing, 에칭, drilling and copper plating, coating with protective layers, and final testing and quality control. Each step ensures that the PCBs meet performance and quality standards.

What maintenance tips are recommended for Mitsubishi BT PCBs?

To extend the lifespan of Mitsubishi BT PCBs, it is recommended to regularly inspect the physical condition of the PCBs, keep them clean, avoid overheating, ensure stable power supply, and adhere to operational guidelines.

QYC 기판

QYC 기판