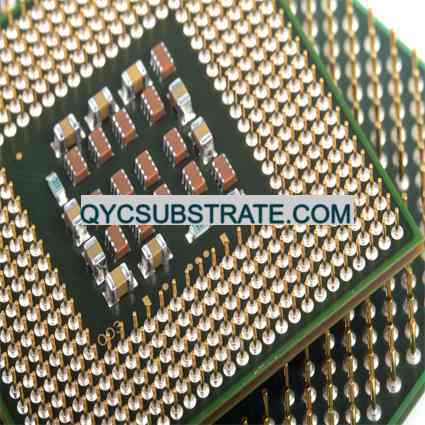

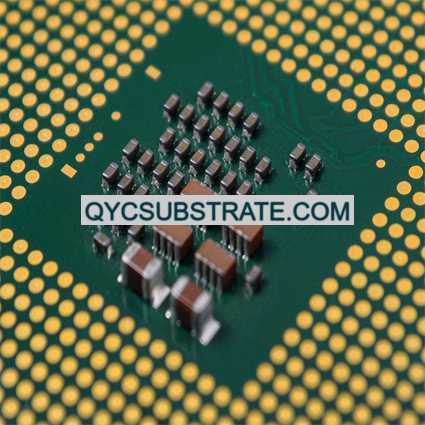

What is Mitsubishi Series PCB/BGA Substrate?

Mitsubishi Series PCB/BGA Substrate Manufacturer.Mitsubishi Series PCB/BGA Substrate Manufacturer is a leading provider of high-quality substrates, specializing in advanced PCB and BGA solutions. Known for their precision engineering and innovative technology, Mitsubishi ensures superior performance and reliability for various electronic applications, from consumer electronics to high-performance computing. Their substrates are designed to meet stringent industry standards, providing excellent thermal management, signal integrity, and mechanical stability. Mitsubishi’s commitment to excellence makes them a trusted partner in the electronics manufacturing industry.

Mitsubishi Series PCB/BGA Substrate refers to a range of high-performance printed circuit board (PCB) materials and ball grid array (BGA) substrates developed by Mitsubishi. These materials are engineered to meet the demands of advanced electronic applications, offering superior electrical and mechanical properties. The Mitsubishi Series PCB/BGA substrates are known for their excellent thermal performance, high reliability, and ability to support high-density interconnects (HDI).

Produttore di substrati PCB/BGA serie Mitsubishi

These substrates are commonly used in various high-end applications, including telecommunications, automotive electronics, aerospace, and consumer electronics. They provide the necessary performance characteristics to handle the complexities of modern electronic devices, ensuring robust and reliable operation even in challenging environments.

The Types of Mitsubishi Series PCB/BGA Substrates

Mitsubishi offers a variety of PCB/BGA substrate types to cater to different application needs:

These laminates feature a high glass transition temperature (Tg), making them suitable for applications that require excellent thermal stability and reliability under high temperatures. They are often used in automotive and aerospace electronics.

These materials have low dielectric constant (Dk) and dissipation factor (Df), ensuring minimal signal loss and high signal integrity. They are ideal for high-frequency and high-speed digital applications, such as telecommunications and data processing.

Environmentally friendly and compliant with global regulations, these laminates are free from halogenated flame retardants. They are used in consumer electronics and other applications where environmental considerations are important.

Designed for applications that generate significant heat, these laminates offer excellent thermal conductivity to efficiently dissipate heat. They are used in power electronics and LED lighting systems.

These laminates combine flexibility and rigidity, providing design versatility for applications requiring both dynamic and static sections, such as wearable electronics and advanced medical devices.

The Advantages of Mitsubishi Series PCB/BGA Substrates

Mitsubishi Series PCB/BGA substrates offer several key advantages that make them suitable for a wide range of applications:

These substrates can withstand high temperatures without degrading, ensuring reliable performance in thermally challenging environments.

The low dielectric constant and dissipation factor of these materials ensure minimal signal loss and high signal fidelity, which is crucial for high-frequency and high-speed digital applications.

Mitsubishi substrates provide excellent mechanical strength and chemical resistance, ensuring long-term reliability and durability even in harsh environments.

Halogen-free laminates comply with environmental regulations, making them suitable for applications where sustainability is a priority.

The availability of various types, including high-Tg, low-Dk, low-Df, high thermal conductivity, flexible, and rigid-flex laminates, offers designers the flexibility to choose the best material for their specific application requirements.

How to Design a PCB with Mitsubishi Series Substrates?

Designing a PCB with Mitsubishi Series substrates involves several critical steps to ensure optimal performance:

Choose the appropriate Mitsubishi substrate material based on the application requirements, considering factors such as thermal performance, signal integrity, and environmental compliance.

Precisely control the impedance of transmission lines to ensure signal integrity. Use electromagnetic simulation software to model and verify the impedance of PCB traces.

Minimize the length of high-frequency signal paths to reduce signal loss and interference. Employ differential pair routing for high-speed differential signals to minimize crosstalk and electromagnetic interference.

Design robust grounding and power distribution networks to ensure stable operation and minimize noise. Utilize ground planes to provide a low-impedance path for return currents.

Incorporate effective thermal management strategies, such as thermal vias and heatsinks, to dissipate heat generated by high-power components and maintain stable operation.

Ensure the PCB design is compatible with standard manufacturing processes. Collaborate closely with the PCB manufacturer to confirm design parameters and fabrication capabilities.

Why Use Mitsubishi Series PCB/BGA Substrates Over Other Boards?

Using Mitsubishi Series PCB/BGA substrates offers several benefits over traditional PCB materials:

The low dielectric constant and low dissipation factor of Mitsubishi substrates ensure superior signal integrity and minimal signal loss, which is essential for high-frequency and high-speed digital applications.

Mitsubishi substrates can withstand high temperatures without degrading, making them ideal for applications that experience significant thermal stress.

These substrates provide excellent mechanical strength and chemical resistance, ensuring long-term reliability and durability in harsh environments.

Halogen-free laminates meet global environmental regulations, making them suitable for applications where sustainability is a priority.

Mitsubishi substrates support various configurations, including high-Tg, low-Dk, low-Df, high thermal conductivity, flexible, and rigid-flex designs, offering greater design flexibility and optimization.

What is the Mitsubishi Series PCB/BGA Substrate Fabrication Process?

The fabrication process of Mitsubishi Series PCB/BGA substrates involves several precise steps to ensure high performance and reliability:

Select and prepare the substrate material according to design specifications. The material should be cut to the required dimensions and cleaned to remove contaminants.

For multilayer PCBs, laminate the individual layers together under high temperature and pressure. Ensure proper alignment and bonding of the layers.

Drill holes for vias and component leads according to the design layout. Precision drilling is essential to maintain the integrity of high-frequency signals.

Plate the drilled holes and vias with copper to create electrical connections between the layers. This step ensures reliable signal transmission and mechanical stability.

Use photolithography to transfer the circuit pattern onto the substrate material. This process involves coating the material with a photosensitive film, exposing it to UV light through a mask, and developing the pattern.

Etch away the unwanted copper to reveal the desired circuit pattern. This step requires precise control to ensure accurate and clean traces.

Apply a surface finish, such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling), to protect the copper traces and ensure good solderability.

Perform electrical testing and visual inspection to verify the PCB’s performance and quality. This includes checking for impedance control, signal integrity, and overall functionality.

The Application of Mitsubishi Series PCB/BGA Substrates

Mitsubishi Series PCB/BGA substrates are used in various high-end applications due to their superior performance and reliability:

These substrates are extensively used in wireless communication systems, including mobile phones, base stations, and satellite communications. They enable high-speed data transmission and efficient signal processing.

Mitsubishi substrates are used in advanced driver-assistance systems (ADAS), radar sensors, and high-speed data communication in modern vehicles. They ensure reliable operation in harsh automotive environments.

These substrates are used in radar systems, satellite navigation, and communication devices in the aerospace industry. Their excellent thermal stability and reliability ensure optimal performance in extreme environments.

Mitsubishi substrates are used in high-performance consumer electronics, such as smartphones, tablets, and wearable devices, ensuring reliable operation and high signal integrity.

These substrates are used in advanced medical devices that require high reliability and precision, such as imaging systems and diagnostic equipment.

FAQs

What are the main advantages of Mitsubishi Series PCB/BGA substrates?

The main advantages include high thermal stability, superior signal integrity, enhanced reliability, environmental compliance, and design versatility.

What application areas are suitable for Mitsubishi Series PCB/BGA substrates?

Mitsubishi Series substrates are suitable for telecommunications, automotive electronics, aerospace, consumer electronics, and medical devices, among others.

What is the difference between Mitsubishi Series substrates and traditional PCB materials?

Mitsubishi Series substrates offer better signal performance, higher thermal stability, and improved reliability in high-frequency and high-speed applications compared to traditional PCB materials, which are typically used for lower frequency and less demanding applications.

What factors should be considered when designing a PCB with Mitsubishi Series substrates?

Factors to consider include material selection, impedance control, signal path layout, grounding and power planes, thermal management, and manufacturability.

SUBSTRATO QYC

SUBSTRATO QYC