What is Silicon Carbide (Sic) Ceramic PCBs?

Carbure de silicium (Sic) Ceramic PCBs Manufacturer.Silicon Carbide (Sic) Ceramic PCBs offer exceptional thermal conductivity, high voltage resistance, and superior mechanical strength, making them ideal for high-power and high-frequency applications. Leading manufacturers specialize in producing these advanced PCBs with precise design tolerances and high reliability, catering to industries like aerospace, automotive, and power electronics. Their expertise ensures optimal performance in extreme environments, enhancing the efficiency and durability of electronic devices.

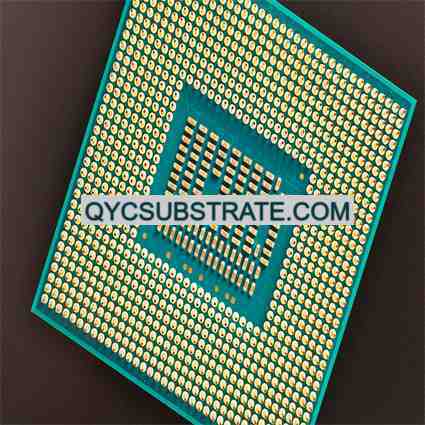

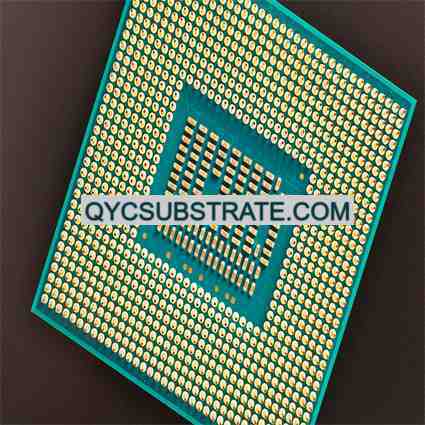

Carbure de silicium (Sic) ceramic PCBs are a type of advanced ceramic circuit board that utilizes silicon carbide as the primary material for the substrate. Silicon carbide is a compound made of silicon and carbon, known for its exceptional hardness, thermal conductivity, and electrical properties. SiC ceramic PCBs leverage these properties to deliver high-performance solutions for demanding electronic applications.

SiC ceramic PCBs are distinguished by their ability to operate efficiently in high-temperature and high-power environments. The material’s high thermal conductivity ensures effective heat dissipation, which is critical in applications involving high power densities. Additionally, SiC’s excellent electrical insulation properties make these PCBs suitable for high-voltage applications, where maintaining electrical isolation is crucial.

The fabrication of SiC ceramic PCBs involves using silicon carbide powder mixed with binders and then sintering at high temperatures to form a solid, rigid substrate. This process results in a board that can withstand extreme conditions while providing reliable electrical performance. SiC PCBs are used in various high-performance and high-reliability applications, including power electronics, RF and microwave devices, and aerospace systems.

The Types of Silicon Carbide (Sic) Ceramic PCBs

Carbure de silicium (Sic) ceramic PCBs come in several types, each tailored to meet specific application requirements. The primary types include single-layer SiC PCBs, multi-layer SiC PCBs, and custom-designed SiC substrates.

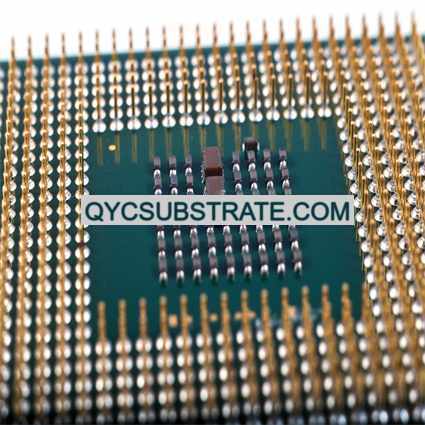

Single-layer SiC PCBs are the simplest form, consisting of a single layer of silicon carbide material. These Les PCB are used in applications where a straightforward circuit design is sufficient. Despite their simplicity, single-layer SiC PCBs benefit from the inherent properties of silicon carbide, such as high thermal conductivity and electrical insulation.

Carbure de silicium (Sic) Fabricant de PCB en céramique

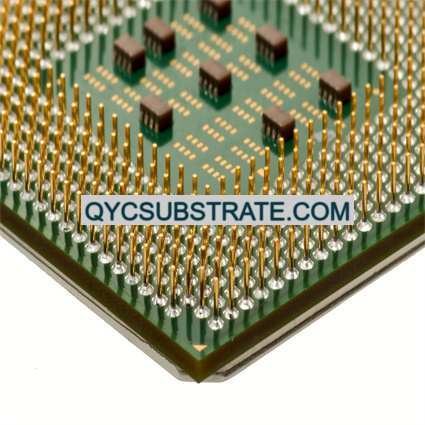

Multi-layer SiC PCBs feature multiple layers of silicon carbide stacked and bonded together. This multilayer structure allows for more complex circuit designs and greater functionality within a compact form factor. Multi-layer SiC PCBs are particularly useful in applications requiring high-density interconnections, Gestion thermique, and integrated components. The ability to stack multiple layers also helps in reducing the size of the overall electronic assembly while maintaining high performance.

Custom-designed SiC substrates are tailored to meet specific needs of advanced applications. These substrates can include unique features such as embedded heat sinks, integrated passive components, or specialized patterns to enhance thermal or electrical performance. Custom designs are often used in cutting-edge technologies where standard SiC PCBs may not meet the required specifications.

Each type of SiC ceramic PCB offers distinct advantages based on the complexity and requirements of the application. Single-layer boards are cost-effective and suitable for simpler designs, while multi-layer and custom-designed SiC PCBs provide enhanced functionality and performance for more demanding applications.

The Advantages of Silicon Carbide (Sic) Ceramic PCBs

Carbure de silicium (Sic) ceramic PCBs offer several significant advantages over traditional PCB materials, making them a preferred choice for high-performance and high-reliability applications.

SiC ceramic PCBs excel in thermal management due to their high thermal conductivity. This property allows for efficient heat dissipation, which is crucial in high-power electronic devices where excess heat can lead to performance degradation or component failure. By effectively managing heat, SiC PCBs ensure stable operation and enhance the longevity of electronic systems.

SiC materials provide excellent electrical insulation, making SiC ceramic PCBs suitable for high-voltage applications. The high breakdown voltage and low electrical loss characteristics of SiC ensure reliable performance in circuits with demanding electrical requirements. This makes SiC PCBs ideal for power electronics, RF and microwave devices, and other high-voltage applications.

Silicon carbide is known for its hardness and mechanical strength. SiC ceramic PCBs are highly resistant to physical stress, vibrations, and shocks, making them suitable for use in harsh environments such as aerospace, automotive, and industrial applications. The durability of SiC PCBs ensures they can withstand demanding conditions without compromising performance.

SiC ceramics can operate at elevated temperatures without significant degradation in performance. This high temperature tolerance is beneficial in applications involving extreme temperatures, such as high-power electronic devices, automotive engines, and aerospace systems. SiC PCBs maintain their mechanical and electrical properties even under high-temperature conditions.

Silicon carbide has excellent chemical resistance, making SiC ceramic PCBs suitable for use in corrosive environments. This property is particularly valuable in applications where the PCB may be exposed to harsh chemicals or environments that could otherwise degrade traditional PCB materials.

In summary, the advantages of SiC ceramic PCBs include high thermal conductivity, superior electrical properties, exceptional mechanical strength, high temperature tolerance, and chemical resistance. These benefits make SiC PCBs a valuable choice for advanced electronic systems that require reliable performance under challenging conditions.

How to Design a Silicon Carbide (Sic) PCB en céramique

Designing a Silicon Carbide (Sic) ceramic PCB involves several key steps to ensure optimal performance and manufacturability. The design process begins with defining the electrical and mechanical requirements of the application, followed by the creation of a detailed circuit schematic and layout.

The first step in designing an SiC ceramic PCB is to clearly define the requirements of the application, including electrical specifications, thermal management needs, and mechanical constraints. Understanding the operating conditions and performance requirements will guide the design choices and material selection.

Choose silicon carbide as the primary substrate material for the PCB. SiC’s properties, such as high thermal conductivity and electrical insulation, make it suitable for high-power and high-voltage applications. Additionally, select appropriate conductive materials for the traces and vias that will be used in conjunction with SiC.

Develop a detailed circuit schematic that outlines the components and their connections. This schematic serves as the foundation for the PCB layout and ensures that all necessary electrical functions are included in the design.

Using PCB design software, create a detailed layout of the SiC PCB. The layout should include the placement of components, routing of conductive traces, and design of thermal management features. Pay close attention to minimizing signal paths, reducing parasitic effects, and ensuring proper spacing to avoid interference.

Integrate thermal management solutions into the SiC PCB design to address heat dissipation needs. This may include features such as thermal vias, heat sinks, or specialized patterns to enhance heat transfer away from high-power components.

Ensure that the design adheres to manufacturing capabilities and constraints. This includes considering factors such as layer alignment, via sizes, and component placement to facilitate efficient fabrication and assembly.

Once the design is complete, it is crucial to verify its performance through simulations and testing. This includes checking electrical performance, thermal management efficiency, and mechanical durability. Any issues identified during this phase should be addressed before proceeding to manufacturing.

Prepare the design files for fabrication, including detailed specifications for the SiC substrate and conductive patterns. Work with a manufacturer experienced in SiC PCB production to ensure high-quality results. The fabrication process will involve sintering the SiC substrate, applying conductive patterns, and assembling the final PCB.

In conclusion, designing a Silicon Carbide (Sic) ceramic PCB involves defining requirements, selecting materials, creating circuit schematics and layouts, integrating thermal management solutions, and ensuring manufacturability. Proper design practices and verification are essential to achieving a high-performance SiC PCB that meets the demanding needs of advanced electronic applications.

Why Use Silicon Carbide (Sic) Ceramic PCBs Over Other Boards?

Carbure de silicium (Sic) ceramic PCBs offer several distinct advantages compared to traditional PCB materials, making them an attractive choice for specific high-performance applications.

SiC ceramic PCBs excel in thermal management due to their high thermal conductivity. This property allows for effective heat dissipation, which is essential in high-power applications where heat buildup can lead to performance issues or component failure. Traditional PCB materials, such as FR4, have lower thermal conductivity and may not effectively manage heat in high-power applications.

SiC provides excellent electrical insulation, making SiC ceramic PCBs suitable for high-voltage applications. The high breakdown voltage and low electrical losses of SiC ensure reliable performance in circuits with demanding electrical requirements. In contrast, traditional PCB materials may have higher electrical losses and lower breakdown voltages, limiting their suitability for high-voltage applications.

SiC ceramics are known for their hardness and mechanical strength. SiC ceramic PCBs offer superior resistance to physical stress, vibrations, and shocks compared to traditional PCB materials. This makes SiC PCBs ideal for use in harsh environments, such as aerospace and automotive applications, where durability and reliability are critical.

Silicon carbide can operate at elevated temperatures without significant degradation in performance. SiC ceramic PCBs are capable of withstanding high temperatures, making them suitable for applications involving extreme thermal conditions. Traditional PCB materials, such as FR4, have lower temperature tolerance and may experience performance degradation or failure under high-temperature conditions.

SiC ceramics have excellent resistance to chemical corrosion, making SiC ceramic PCBs suitable for use in environments exposed to harsh chemicals or corrosive substances. This property is beneficial for applications in chemical processing, industrial environments, and other scenarios where traditional PCB materials may be susceptible to chemical damage.

SiC ceramic PCBs allow for the integration of advanced features, such as embedded heat sinks, passive components, and custom designs, to meet specific application needs. This level of integration and customization is often challenging to achieve with traditional PCB

materials, which may require additional components or design modifications.

In summary, Carbure de silicium (Sic) ceramic PCBs offer several advantages over traditional PCB materials, including high thermal conductivity, superior electrical performance, exceptional mechanical properties, high temperature tolerance, and chemical resistance. These benefits make SiC ceramic PCBs a preferred choice for demanding applications in high-power, high-voltage, and harsh environments.

What is the Silicon Carbide (Sic) Processus de fabrication de PCB?

The fabrication process of Silicon Carbide (Sic) ceramic PCBs involves several specialized steps to produce a high-performance circuit board that leverages the unique properties of silicon carbide. The process begins with the preparation of SiC substrates and progresses through various stages to achieve the final PCB.

The process starts with the preparation of silicon carbide powder, which is mixed with binders and additives to form a ceramic paste. This paste is then used to create the SiC substrate. The mixture is carefully controlled to ensure the desired properties of the final PCB, including thermal conductivity, electrical insulation, and mechanical strength.

The SiC paste is shaped into substrates using techniques such as pressing, extrusion, or casting. The substrates are then dried and subjected to a high-temperature sintering process to fuse the silicon carbide particles together and form a solid, rigid material. The sintering temperature typically ranges from 2000°C to 2500°C, depending on the specific SiC formulation.

Once the SiC substrates are prepared, the next step is to pattern the conductive elements onto the substrate. This is typically done using techniques such as screen printing or sputtering to apply metal layers, such as copper or silver, onto the SiC surface. The conductive patterns form the electrical traces, pads, and vias needed for the PCB.

If the design involves multiple layers, the patterned SiC substrates are laminated together using high-pressure and high-temperature processes. This step ensures that the layers are firmly bonded and aligned to create a multi-layer PCB. Additional components, such as heat sinks or passive elements, may be integrated during this stage.

The laminated SiC PCB undergoes a co-firing process, where it is heated in a kiln at temperatures exceeding 2000°C. During co-firing, the metal patterns sinter and bond to the SiC substrate, creating a durable and electrically conductive network. The high temperature also ensures that the ceramic substrate achieves its final strength and stability.

After co-firing, the PCB may undergo surface finishing processes to enhance its performance and appearance. This may include plating with gold or other metals to improve solderability and protect the conductive traces. Surface finishes also help to ensure reliable electrical connections and prevent oxidation.

The final step in the fabrication process involves rigorous testing and inspection to ensure that the SiC PCB meets the required specifications. This includes electrical testing to verify connectivity and performance, dimensional inspection to ensure accuracy, and environmental testing to evaluate the PCB’s performance under various conditions.

In conclusion, the fabrication process of Silicon Carbide (Sic) ceramic PCBs involves material preparation, substrate formation, patterning, laminage, co-firing, surface finishing, and testing. Each step is carefully controlled to produce high-performance SiC PCBs that leverage the unique properties of silicon carbide for advanced electronic applications.

The Application of Silicon Carbide (Sic) Ceramic PCBs

Carbure de silicium (Sic) ceramic PCBs are used in a wide range of applications due to their exceptional properties, including high thermal conductivity, electrical insulation, and mechanical strength. These properties make SiC PCBs well-suited for demanding environments and high-performance systems.

SiC ceramic PCBs are commonly used in power electronics applications, such as power converters, inverters, and motor drives. The high thermal conductivity of SiC helps to manage heat dissipation in high-power devices, ensuring reliable operation and efficiency. SiC PCBs are particularly valuable in applications involving high power densities and rapid switching.

The excellent electrical properties of SiC make it ideal for RF and microwave applications. SiC ceramic PCBs are used in communication systems, radar equipment, and satellite technology, where high-frequency signal integrity is crucial. The low electrical losses and high breakdown voltage of SiC ensure reliable performance in these demanding applications.

SiC ceramic PCBs are employed in aerospace and defense systems due to their durability and high temperature tolerance. Applications include satellite systems, avionics, and missile guidance systems. SiC PCBs can withstand extreme conditions, such as high altitudes, temperature variations, and mechanical stresses, making them suitable for critical aerospace and defense applications.

In the automotive industry, SiC ceramic PCBs are used in advanced driver assistance systems (ADAS), power electronics, and engine control units (ECUs). The ability of SiC PCBs to endure high temperatures and vibrations makes them suitable for automotive environments, where reliability and performance are essential.

SiC ceramic PCBs find use in various industrial applications, including high-temperature sensors, control systems, and industrial power supplies. The chemical resistance and mechanical strength of SiC make it suitable for harsh industrial environments where traditional PCB materials may not perform adequately.

SiC PCBs are used in high-temperature electronic systems, such as geothermal and aerospace applications, where traditional PCBs would fail due to thermal degradation. The high temperature tolerance of SiC ensures that these PCBs maintain their performance and reliability even under extreme conditions.

In summary, Carbure de silicium (Sic) ceramic PCBs are utilized in diverse applications, including power electronics, RF and microwave devices, aerospace and defense systems, automotive electronics, industrial applications, and high-temperature electronics. The unique properties of SiC make these PCBs a valuable choice for high-performance and reliability-critical applications across various industries.

Foire aux questions

What are the main advantages of Silicon Carbide (Sic) ceramic PCBs?

Carbure de silicium (Sic) ceramic PCBs offer high thermal conductivity, superior electrical insulation, exceptional mechanical strength, high temperature tolerance, and chemical resistance. These advantages make SiC PCBs ideal for high-power, high-voltage, and harsh environment applications.

How are Silicon Carbide (Sic) ceramic PCBs different from traditional PCB materials?

SiC ceramic PCBs differ from traditional materials in their high thermal conductivity, superior electrical performance, and mechanical strength. Unlike traditional PCB materials, SiC can operate at higher temperatures and withstand harsher conditions, making it suitable for demanding applications.

What are the typical applications of SiC ceramic PCBs?

SiC ceramic PCBs are used in power electronics, RF and microwave devices, aerospace and defense systems, automotive electronics, industrial applications, and high-temperature electronics. Their unique properties make them suitable for high-performance and reliability-critical applications.

What is the fabrication process for SiC ceramic PCBs?

The fabrication process involves material preparation, substrate formation, patterning of conductive elements, laminage (if multi-layered), co-firing, surface finishing, and rigorous testing. Each step is designed to ensure the high performance and durability of the final SiC PCB.

Can SiC ceramic PCBs be used in high-temperature environments?

Yes, SiC ceramic PCBs are well-suited for high-temperature environments due to their high temperature tolerance and thermal stability. They maintain their performance and reliability even under extreme thermal conditions.

SUBSTRAT QYC

SUBSTRAT QYC