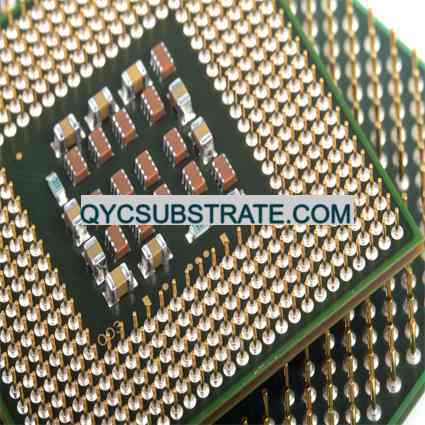

What is Mitsubishi Series PCB/BGA Substrate?

Mitsubishi Series PCB/BGA Substrate Manufacturer.Mitsubishi Series PCB/BGA Substrate Manufacturer is a leading provider of high-quality substrates, specializing in advanced PCB and BGA solutions. Known for their precision engineering and innovative technology, Mitsubishi ensures superior performance and reliability for various electronic applications, from consumer electronics to high-performance computing. Their substrates are designed to meet stringent industry standards, providing excellent thermal management, Signalintegrität, and mechanical stability. Mitsubishi’s commitment to excellence makes them a trusted partner in the electronics manufacturing industry.

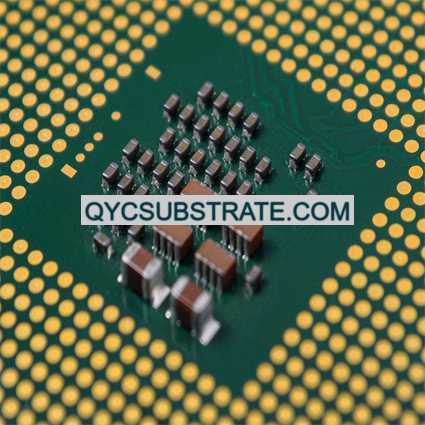

Mitsubishi Series PCB/BGA Substrate refers to a range of high-performance printed circuit board (PLATINE) materials and ball grid array (BGA) substrates developed by Mitsubishi. These materials are engineered to meet the demands of advanced electronic applications, offering superior electrical and mechanical properties. The Mitsubishi Series PCB/BGA substrates are known for their excellent thermal performance, high reliability, and ability to support high-density interconnects (HDI).

Hersteller von PCB/BGA-Substraten der Mitsubishi-Serie

These substrates are commonly used in various high-end applications, including telecommunications, automotive electronics, Luft- und Raumfahrt, and consumer electronics. They provide the necessary performance characteristics to handle the complexities of modern electronic devices, ensuring robust and reliable operation even in challenging environments.

The Types of Mitsubishi Series PCB/BGA Substrates

Mitsubishi offers a variety of PCB/BGA substrate types to cater to different application needs:

These laminates feature a high glass transition temperature (TG), making them suitable for applications that require excellent thermal stability and reliability under high temperatures. They are often used in automotive and aerospace electronics.

These materials have low dielectric constant (Dk) and dissipation factor (Df), Gewährleistung von minimalen Signalverlusten und hoher Signalintegrität. They are ideal for high-frequency and high-speed digital applications, such as telecommunications and data processing.

Environmentally friendly and compliant with global regulations, these laminates are free from halogenated flame retardants. They are used in consumer electronics and other applications where environmental considerations are important.

Designed for applications that generate significant heat, these laminates offer excellent thermal conductivity to efficiently dissipate heat. They are used in power electronics and LED lighting systems.

These laminates combine flexibility and rigidity, providing design versatility for applications requiring both dynamic and static sections, such as wearable electronics and advanced medical devices.

The Advantages of Mitsubishi Series PCB/BGA Substrates

Mitsubishi Series PCB/BGA substrates offer several key advantages that make them suitable for a wide range of applications:

These substrates can withstand high temperatures without degrading, ensuring reliable performance in thermally challenging environments.

The low dielectric constant and dissipation factor of these materials ensure minimal signal loss and high signal fidelity, which is crucial for high-frequency and high-speed digital applications.

Mitsubishi substrates provide excellent mechanical strength and chemical resistance, Gewährleistung langfristiger Zuverlässigkeit und Langlebigkeit auch in rauen Umgebungen.

Halogen-free laminates comply with environmental regulations, making them suitable for applications where sustainability is a priority.

The availability of various types, including high-Tg, low-Dk, low-Df, high thermal conductivity, flexible, and rigid-flex laminates, offers designers the flexibility to choose the best material for their specific application requirements.

How to Design a PCB with Mitsubishi Series Substrates?

Designing a PCB with Mitsubishi Series substrates involves several critical steps to ensure optimal performance:

Choose the appropriate Mitsubishi substrate material based on the application requirements, considering factors such as thermal performance, Signalintegrität, and environmental compliance.

Präzise Kontrolle der Impedanz von Übertragungsleitungen, um die Signalintegrität zu gewährleisten. Use electromagnetic simulation software to model and verify the impedance of PCB traces.

Minimieren Sie die Länge hochfrequenter Signalwege, um Signalverluste und Interferenzen zu reduzieren. Verwenden Sie differentielles Paar-Routing für differentielle Hochgeschwindigkeitssignale, um Übersprechen und elektromagnetische Interferenzen zu minimieren.

Entwerfen Sie robuste Erdungs- und Stromverteilungsnetze, um einen stabilen Betrieb zu gewährleisten und das Rauschen zu minimieren. Verwendung von Masseflächen, um einen niederohmigen Pfad für Rückströme bereitzustellen.

Integrieren Sie effektive Wärmemanagementstrategien, wie z. B. Thermal Vias und Kühlkörper, zur Ableitung der von Hochleistungskomponenten erzeugten Wärme und zur Aufrechterhaltung eines stabilen Betriebs.

Stellen Sie sicher, dass das PCB-Design mit den Standard-Fertigungsprozessen kompatibel ist. Collaborate closely with the PCB manufacturer to confirm design parameters and fabrication capabilities.

Why Use Mitsubishi Series PCB/BGA Substrates Over Other Boards?

Using Mitsubishi Series PCB/BGA substrates offers several benefits over traditional PCB materials:

The low dielectric constant and low dissipation factor of Mitsubishi substrates ensure superior signal integrity and minimal signal loss, which is essential for high-frequency and high-speed digital applications.

Mitsubishi substrates can withstand high temperatures without degrading, making them ideal for applications that experience significant thermal stress.

These substrates provide excellent mechanical strength and chemical resistance, ensuring long-term reliability and durability in harsh environments.

Halogen-free laminates meet global environmental regulations, making them suitable for applications where sustainability is a priority.

Mitsubishi substrates support various configurations, including high-Tg, low-Dk, low-Df, high thermal conductivity, flexible, and rigid-flex designs, offering greater design flexibility and optimization.

What is the Mitsubishi Series PCB/BGA Substrate Fabrication Process?

The fabrication process of Mitsubishi Series PCB/BGA substrates involves several precise steps to ensure high performance and reliability:

Select and prepare the substrate material according to design specifications. Das Material sollte auf die erforderlichen Abmessungen zugeschnitten und gereinigt werden, um Verunreinigungen zu entfernen.

Für Multilayer-Leiterplatten, Laminieren Sie die einzelnen Schichten unter hoher Temperatur und hohem Druck miteinander. Stellen Sie sicher, dass die Schichten richtig ausgerichtet und verbunden sind.

Bohrungen von Löchern für Durchkontaktierungen und Bauteilanschlüsse entsprechend dem Designlayout. Präzisionsbohrungen sind unerlässlich, um die Integrität hochfrequenter Signale zu erhalten.

Plattieren Sie die Bohrlöcher und Durchkontaktierungen mit Kupfer, um elektrische Verbindungen zwischen den Schichten herzustellen. Dieser Schritt gewährleistet eine zuverlässige Signalübertragung und mechanische Stabilität.

Use photolithography to transfer the circuit pattern onto the substrate material. Bei diesem Verfahren wird das Material mit einer lichtempfindlichen Folie beschichtet, Er wird durch eine Maske UV-Licht ausgesetzt, und Entwicklung des Musters.

Ätzen Sie das unerwünschte Kupfer weg, um das gewünschte Schaltungsmuster freizulegen. Dieser Schritt erfordert eine präzise Kontrolle, um genaue und saubere Spuren zu gewährleisten.

Auftragen einer Oberflächenveredelung, wie z.B. ENIG (Chemisches Nickel-Immersionsgold) oder HASL (Nivellierung von Heißluftlötmitteln), zum Schutz der Kupferleiterbahnen und zur Gewährleistung einer guten Lötbarkeit.

Führen Sie elektrische Tests und Sichtprüfungen durch, um die Leistung und Qualität der Leiterplatte zu überprüfen. Dazu gehört auch die Überprüfung der Impedanzkontrolle, Signalintegrität, und allgemeine Funktionalität.

The Application of Mitsubishi Series PCB/BGA Substrates

Mitsubishi Series PCB/BGA substrates are used in various high-end applications due to their superior performance and reliability:

These substrates are extensively used in wireless communication systems, einschließlich Mobiltelefone, Basisstationen, und Satellitenkommunikation. Sie ermöglichen eine Hochgeschwindigkeits-Datenübertragung und eine effiziente Signalverarbeitung.

Mitsubishi substrates are used in advanced driver-assistance systems (ADAS), Radarsensoren, und Highspeed-Datenkommunikation in modernen Fahrzeugen. Sie gewährleisten einen zuverlässigen Betrieb in rauen Automobilumgebungen.

These substrates are used in radar systems, Satellitennavigation, und Kommunikationsgeräte in der Luft- und Raumfahrtindustrie. Ihre hervorragende thermische Stabilität und Zuverlässigkeit gewährleisten eine optimale Leistung in extremen Umgebungen.

Mitsubishi substrates are used in high-performance consumer electronics, such as smartphones, tablets, and wearable devices, ensuring reliable operation and high signal integrity.

These substrates are used in advanced medical devices that require high reliability and precision, such as imaging systems and diagnostic equipment.

Häufig gestellte Fragen

What are the main advantages of Mitsubishi Series PCB/BGA substrates?

The main advantages include high thermal stability, superior signal integrity, enhanced reliability, environmental compliance, and design versatility.

What application areas are suitable for Mitsubishi Series PCB/BGA substrates?

Mitsubishi Series substrates are suitable for telecommunications, automotive electronics, Luft- und Raumfahrt, consumer electronics, and medical devices, unter anderem.

What is the difference between Mitsubishi Series substrates and traditional PCB materials?

Mitsubishi Series substrates offer better signal performance, higher thermal stability, and improved reliability in high-frequency and high-speed applications compared to traditional PCB materials, which are typically used for lower frequency and less demanding applications.

What factors should be considered when designing a PCB with Mitsubishi Series substrates?

Zu den zu berücksichtigenden Faktoren gehören die Materialauswahl, Impedanzkontrolle, Layout des Signalpfads, Erdung und Power Plans, Thermomanagement, und Herstellbarkeit.

QYC-SUBSTRAT

QYC-SUBSTRAT